Ponticon’s pontiMAT system enables rapid alloy development

October 5, 2021

Ponticon, Wiesbaden, Germany, will showcase its pontiMAT system, a process that supports the development of metallic alloys for use in Additive Manufacturing, at Formnext 2021. The pontiMAT system is said to enable users to rapidly produce and test samples of a wide range of application-specific materials, using minimum resources.

The new system is based on Extreme High-Speed Laser Metal Deposition (EHLA) technology, a high-speed Direct Energy Deposition (DED) process conceived and developed into a market-ready product by Ponticon in close cooperation with the Fraunhofer Institute for Laser Technology (ILT), Aachen, Germany, and the chair for Digital Additive Production (DAP) at RWTH Aachen University.

In addition to being able to combine an extremely wide and diverse range of alloying elements, the pE3D system employed enables the molten material to solidify at specific rates within a very wide range, namely from 100 K/s to 10 million K/s. Thus, the microstructural features can be influenced within unprecedented limits.

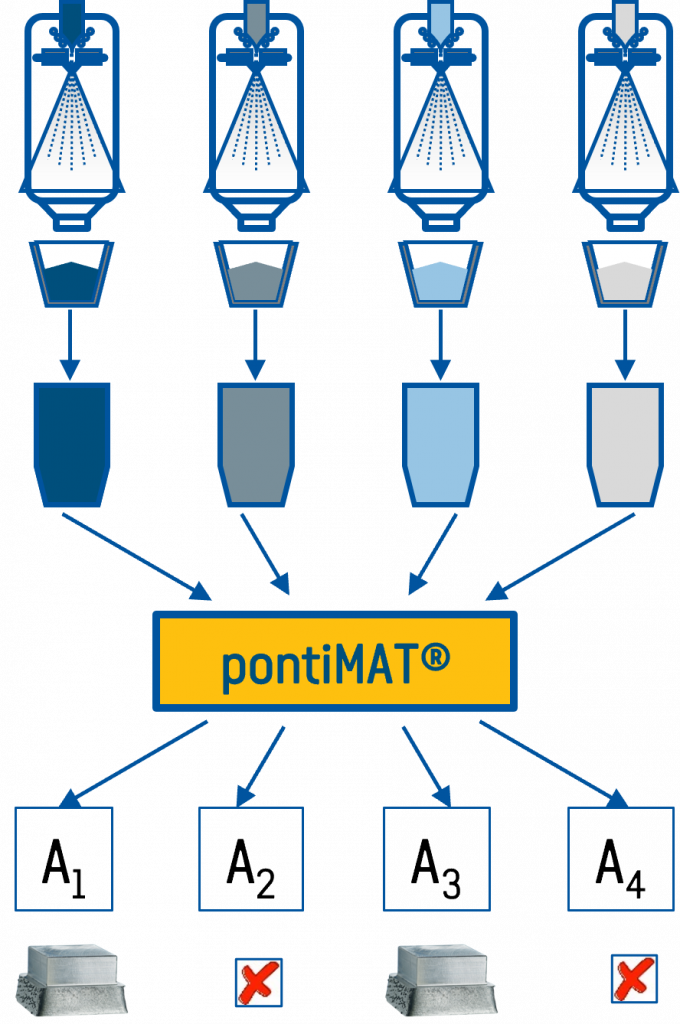

The system can be very helpful in speeding up the development of alloys for specific applications. Here, it can be used to quickly additively manufacture samples for metallurgical analysis, reputedly enabling hundreds of alloying variants per day to be processed into samples and tested. It’s in this way that the new system dramatically reduces the effort otherwise involved in conventional sample melting and analysis methods.

“From a design perspective, many components are designed and optimised for their suitability for Additive Manufacturing,” stated Tobias Stittgen, Managing Director of Ponticon GmbH. “However, the optimisation of the materials has a significantly higher potential for functionality enhancement. When our customers use our pontiMAT system in the development of new, application-specific AM alloys, they can achieve some 50% performance improvement from their products – not just 5% or 10%.”

The EHLA process in detail

In contrast to conventional laser deposition methods, the EHLA melts the metal powder before it reaches the surface of the substrate, on which it is deposited in successive layers.

A central element of the system is the laser head with the integrated powder nozzle. The head is designed so the light emitted by a laser of several kW capacity is focused a few millimetres above the surface. The metal powder is fed into the laser beam by means of a nozzle specifically designed for the EHLA system.

Different alloying materials are reportedly able to be mixed in virtually any combination. For this, up to eight powder feeders are available for up to eight different metallic elements or pre-blended alloys. This makes the system suitable for systematic analysis and testing of high-entropy alloys and their specific properties and, because of their capacity to adopt a wide variety of material properties, these alloys are of great interest to materials scientists.

In order to achieve high relative velocities between the deposition head and the additively manufactured component, the head – including the laser optics and the powder nozzle – is fix-mounted, while the plate that serves as the substrate for the end component is arranged on a movable tripod below the nozzle. The linear kinematics specially designed for this process make it possible to achieve very high acceleration rates and process speeds while still manufacturing with the highest precision.

Operation of the pE3D system necessitates extreme mechanical stability. Because of this, the system is mounted on a structure made of 200 mm-thick granite plates surface-ground with a tolerance of just 5 µm.

The AM process is precisely controllable by means of finely adjusted key parameters such as the laser power, laser beam diameter, mass flow of the powder and moving velocity of the substrate carrier.