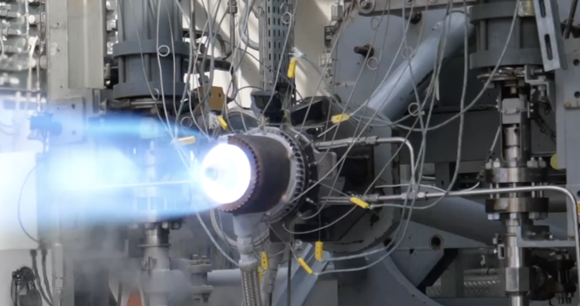

Pangea Aerospace successfully hot fires AM aerospike engine

November 17, 2021

Pangea Aerospace, Barcelona, Spain, has successfully hot fired what is reputed to be the first dual regeneratively cooled aerospike engine, DemoP1, at the German Aerospace Center (DLR) facilities in Lampoldshausen. Pangea credits the Additive Manufacturing, done by Aenium, Valladolid, Spain, and the use of new materials with its ability to improve the thermal qualities of aerospike engines.

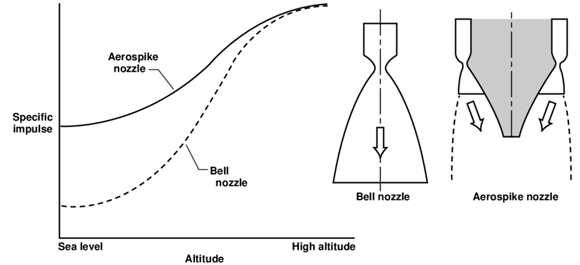

These engines have been sought after since they were first theorised in the 1950s, but, despite testing in the ’80s and ’90s, no aerospike engine has ever flown. In part, this has been due to the high cost of manufacturing and engineering difficulties relating to cooling.

Aerospike engines use a ‘V’ shaped nozzle to direct the exhaust gases that propel the rocket. As the nozzle is open, exhaust gases are always being expelled due to changing ambient pressure. This unique ability means a 15% efficiency increase compared to bell nozzles – in other words, 15% less fuel is required to bring the same mass into orbit.

Aenium additively manufactured the component using GRCop-42, a copper-chrome-niobium alloy developed by NASA, for which it currently has exclusive European capabilities. As the engine was additively manufactured in only two pieces, its productions costs are reported to be extremely low.

Pangea Aerospace designed a new regenerative cooling system using liquid oxygen and liquid methane (both in cryogenic state) as propellants. These go through cooling channels before being ignited in the combustion chamber, thus allowing the propellants to cool the engine.

Miguel Ampudia, CEO of Aenium, stated, “Thanks to GRCop-42 and Aenium’s technology, we have been able to manufacture this engine, which has one of the most complex designs. We are really proud to be able to manufacture this together with Pangea Aerospace, as it will help power tomorrow’s space endeavours.”

Pangea has recently been awarded a contract from CNES (French Space Agency) to begin a study on how this proprietary technology could be applied to larger engines. The company has also reported interest from other commercial organisations and space agencies.