Open Architecture Additive Manufacturing project investigates DED for aerospace

August 14, 2018

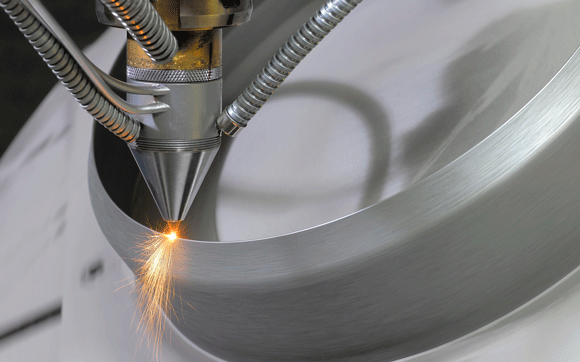

Directed Energy Deposition metal Additive Manufacturing in action (Courtesy TWI Ltd)

Independent research and technology organisation TWI Ltd, Cambridge, UK, is leading the Open Architecture Additive Manufacturing (OAAM) project, with partners including Airbus, Autodesk, Cranfield University, Glenalmond Group, University of Bath, University of Manchester and University of Stratchclyde. The aim of the project is to demonstrate the ability to manufacture large metallic components using metal Additive Manufacturing for the benefit of UK aerospace.

The OAAM programme plans to develop Directed Energy Deposition (DED) AM technologies that can be scaled up for the manufacture of components at the multi-metre scale. Working with the project partners, TWI will create three DED AM process platforms to enable aerospace manufacturers and their supply chains to develop advanced AM manufacturing concepts in the following fields:

- Arc-wire / Laser-wire AM – Cranfield University

- Electron Beam wire AM – TWI Cambridge

- Laser-powder / laser-wire AM – TWI Yorkshire Technology Centre

Each of these systems is expected to offer unique AM capabilities and address a number of common needs such as scalable architecture solutions, with common CAD/CAM control interfacing, integrated process steps (NDT, machining, inspection, cold-work, etc.) as necessary for optimum implementation to aerospace requirements, and the ability to additively manufacture aerospace components to TRL 6 or MCRL 4/5. Each system will be made available to UK industry.

TWI commented that this will offer the UK aerospace sector access to next-generation manufacturing with a simplified, lower risk route to support AM’s industrialisation and rapidly deploy into aircraft platforms. It also foresees a substantial amount of results overspill into other sectors such as the energy and marine industries.

The project is supported by Innovate UK and began in January 2018. It is expected to run for three years in total.