Oerlikon Metco installs gantry system for laser cladding and AM

May 19, 2021

Oerlikon Metco, headquartered in Winterthur, Switzerland, has installed a new seven-axis capable gantry system for Additive Manufacturing and laser cladding at its Swiss Laser Center of Competence. Oerlikon made the purchase in hopes of strengthening the offerings provided by its coating shop as well as furthering its R&D activities.

Laser cladding has existed in the market for over forty years, but is still one of the younger methods for applying an engineered surface. In the past, the adoption of this method was hampered due to cost of the method itself and the relatively high-cost markets in which the application was suited. However, in the last decade, the situation has changed, with laser cladding now one of the most promising deposit methods, combining reasonable cost and quality benefits. In addition to high-quality deposits with a metallurgical bond to the substrate, a key reason for its latest success is related to the multi-function capability of the process.

The upward trend branches into three main directions: Additive Manufacturing, high-speed deposition, and/or high-power deposition. With laser cladding, it is possible to additively manufacture structures layer by layer directly on the surface of components, thus changing the design, which has resulted in the grouping of laser cladding with Direct Energy Deposition (DED) AM processes. The harnessing of this technology may open new horizons for AM and the production or repair of complex multi-dimensional components. With the market demanding ‘first-time-right’ components for AM processes, there has been a leap in developing tailored system technology and process monitoring tools.

Fundamentals of Laser Cladding

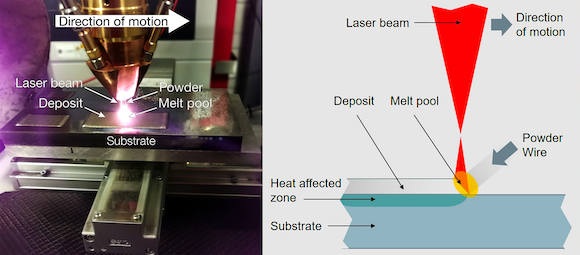

In laser cladding, a laser beam is transferred to the substrate surface where it creates a spot on the surface at which heat will be introduced. The main benefit is that, with the help of optical components (fibres, lenses, collimators), the geometry and dimensions of a produced spot can be defined and controlled.

At the spot, a melt bath is produced on the surface of the substrate. In parallel, feedstock material (in the form of powder or wire) is transferred into the melt pool area, where it melts and builds a deposit on the surface of the base material. As the process happens during the motion of a part or working head, welding seams of defined size are built on the surface (the width is typically equal to the spot size of the laser beam). For applications that require coverage of a larger surface, those seams have to be overlapped with the next passes, building multiple beads.