nTopology update enables real-time visualisation of complex structures

April 23, 2021

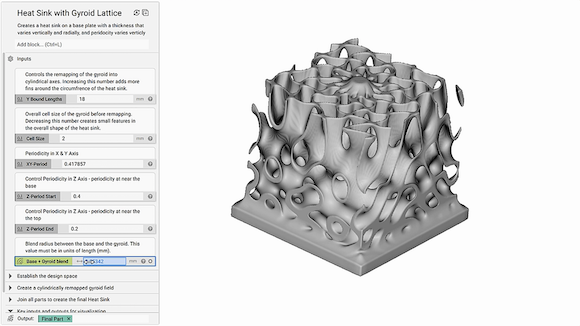

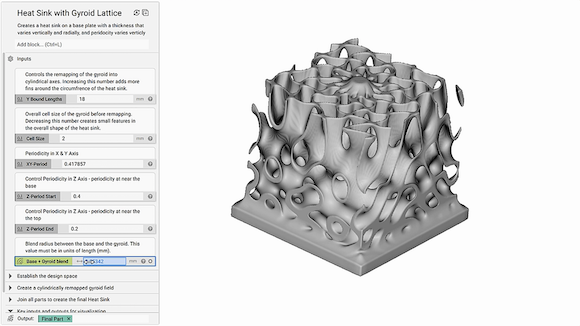

nTopology, New York City, USA, has released an update to its software, nTopology 3.0, which introduces real-time visualisations with GPU accelerations. The company states that limitations in design software is a common barrier to the broader adoption of Additive Manufacturing; with this latest update, the generation of lattices or design changes in complex structures is said to take place almost instantaneously.

On top of this, nTopology 3.0 consolidates the incremental improvements the software saw over the last few months, including functional latticing workflows, topology optimisation tools, expanded engineering simulation utilities and advanced design automation capabilities.

Previously, the software utilised CPUs to visualise parts; more complex parts, such as those with lattice structures, could take tens of seconds to appear. nTopology believes that even this short waiting time could hinder the productivity of its engineering users. As a result, nTopology 3.0 functions on both the CPU and GPU of a user’s system which enables a user to view those complex parts in only up to a few seconds.

Functional latticing workflows have also been a relatively recent update. Using performance requirements as input, a user can act as an architect based on the material responses required for each application. In addition to ordered, stochastic, and TPMS unit cells, nTopology enables users to control lattice properties at every point using simulation results, test data, engineering formulas and a field-driven design approach.

nTopology states that design automation is at its core, from reusable workflows to batch processing through a programmatic environment with with nTopCL, nTopology’s command-line interface. This enables users to call generative nTop workflows in Python or Matlab scripts and can run on desktops, private servers, or the cloud. nTopology can also be integrated into Multidisciplinary Design Optimisation workflows in some third-party softwares, enabling the running of massive computational Design of Experiments.

The topology optimisation has also been improved upon in nTopology 3.0, with new algorithms and constraints unique to AM, as well as automated geometry reconstruction and smoothening tools and the range of post-optimisation options.

Current users of nTopology can access all new functionality by updating their softer. New users can download and install a preview version by creating a free nTop account.