Norsk Titanium brings Additive Manufacturing to semiconductor industry

February 27, 2023

Norsk Titanium, headquartered in Hønefoss, Norway, has announced delivery of its first additively manufactured near-net-shape titanium components to the semiconductor manufacturing market. The 80 kg carrier tray was developed in partnership with Hittech Group, based in Den Haag, Netherlands, and is a critical component of semiconductor manufacturer ASML’s lithography system.

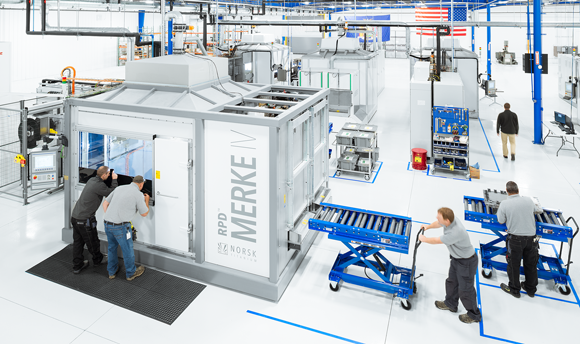

Made using Norsk Titanium’s Rapid Plasma Deposition® (RPD®) technology, a proprietary form of wire-based Directed Energy Deposition (DED), the company is supplying the Ti-6Al-4V preforms into an existing supply chain that delivers the carrier tray to ASML.

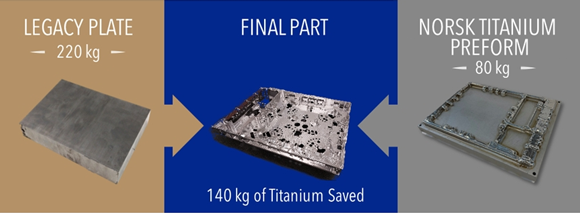

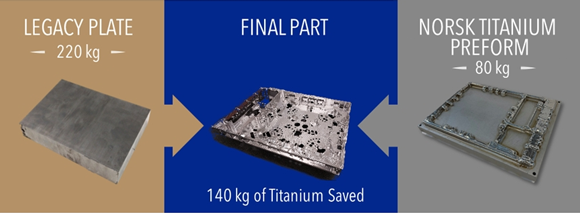

The additively manufactured titanium carrier tray replaces a forged plate and saves 140 kg (64%) in raw materials, whilst allowing the customer to utilise the existing supply chain and expand its current capacity without any further capital investment.

“We are seeing that customers in all markets are looking for alternatives to their legacy titanium suppliers. With this delivery, we have demonstrated that Norsk Titanium can deliver shorter lead times and offer an alternative to titanium raw material suppliers that may be experiencing disruptions in today’s environment,” stated Nicholas Mayer, Norsk Titanium VP of Commercial. “Norsk Titanium is delivering a sustainable alternative to legacy forgings that is compatible with existing Ti6-4 material specifications and production methods. As we expand production in our core aerospace and industrial markets, we continue to prove the value our additive solution brings to our customers.”

Production of the initial preforms took place in Norsk Titanium’s engineering and development centre in Hønefoss and has transitioned to the company‘s production centre in Plattsburgh, New York, USA.

Download Metal AM magazine