NIT’s short-wave infrared imaging provides unique view of melt pool

May 23, 2019

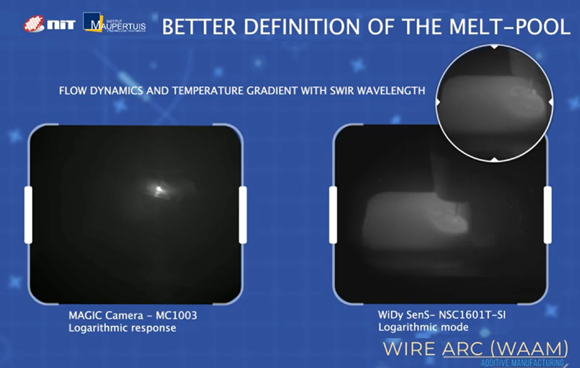

Video footage highlighting the improved definition seen using short-wave infrared imaging (Courtesy NIT)

New Imaging Technologies (NIT), a specialist supplier of imaging sensors and cameras, headquartered in Paris, France, has demonstrated the use of its Short-Wave Infrared (SWIR) imaging systems to monitor the metal Additive Manufacturing process. Working in conjunction with the Institut Maupertuis, a French research centre specialised in automated production processes, the company has released detailed footage of the melt pool formed during certain metal Additive Manufacturing processes.

When dealing with metals, the company states, laser wavelength has to be carefully selected in a region where the metal absorption level is at its maximum. Common metal materials, such as aluminium, copper, chromium, Iron, nickel, tungsten or even platinum have their maximum absorption in a wavelength region between 1-2 μm, contrary to polymer where the maximum absorption wavelength is above 10 μm.

A camera, with the appropriate wavelength, will give the operator the ability to clearly optimise the fabrication processes. Having imaging information or analysis on the melt pool, during the operation of the AM machine, could provide valuable information for process optimisation and in-line quality control, the company states.

In the video footage, NIT illustrates how its WiDy SenS SWIR camera performs in the very high flux scenes of the melt pool in wire-arc Additive Manufacturing (WAAM) and laser Additive Manufacturing processes. Thanks to its high dynamic range, the true shape and geometry of the melt pool can be scene without any blooming effect. The camera can operate up to several hundred frames per second, making it possible to capture fast Additive Manufacturing processes without losing details, such as the ejected droplets around the melt pools.

Watch the video footage here

www.new-imaging-technologies.com