Swisslog and Concept Laser look to develop automated handling systems

December 6, 2016

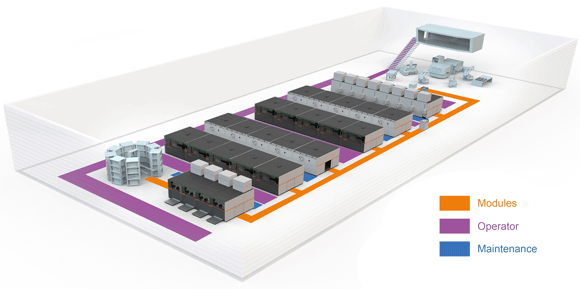

Concept Laser has announced it has entered into a strategic development partnership with Swisslog, a member of the KUKA Group, to deliver an innovative Automated Guided Vehicle (AGV) system for industrial Additive Manufacturing environments. The demand for automation is a further step in Concept Laser’s development of its ‘AM Factory of Tomorrow’ utilising the company’s M Line Factory systems.

Concept Laser stated that it will become the first manufacturer of machines and installations for metal Additive Manufacturing to embrace an automation solution for moving modules between the different machine units and within the production environments. The company is seeking to implement automated solutions as part of the process of manufacturing additive metal parts.

“The ambitious concept of the M Line Factory ensures a high level of automation and flexibility in 3D metal printing. The AGV system from Swisslog is the next stage in the development toward consistent automation of the processes embracing the basic idea of Industry 4.0,” stated Dr Florian Bechmann, Head of Research & Development at Concept Laser.

Swisslog brings its many years of expertise in the automation of material flow and intralogistics to this partnership. As a provider of flexible robotic and data-driven automated solutions for warehouses and distribution centres, Swisslog’s AGV system is regarded as a key strategic element of the new M Line Factory from Concept Laser. Swisslog’s task is specifically to integrate a driverless transport system with smart software for fleet management and power supply to ensure that modules can be moved between different machine units or within an AM factory.

By contrast, Concept Laser is responsible for the set-up on top of the AGV in order to move powder or parts in an autonomous way. In addition, the company is also responsible for the docking including the receipt and transfer of the modules.

The planned approach pursues two objectives. Firstly, the AGV system should be capable of moving modules between the machine units or within a production environment,and, secondly, it is all about the intralogistics in the factory for the reliable and automated supply of powder material and preparation. “With this collaboration we see the opportunity to implement our highly efficient automated solutions for smart logistics networks in production,” added Dr Christian Baur, CEO of Swisslog’s Warehouse and Distribution Solutions division.

The background to the demand for automated systems is the separation of production and processing units. The new machine architecture from Concept Laser, the M Line Factory, means that it is possible to arrange the units physically separate from each other. This now enables processes that previously had to take place sequentially to run in parallel, which ultimately saves both time and money in the production of additive metal parts.