NCAME researchers awarded grant for additive nanomanufacturing of multifunctional materials

February 1, 2020

Two researchers from Auburn University’s National Center for Additive Manufacturing Excellence (NCAME), Auburn, Alabama, USA, have been awarded a $400,000 National Science Foundation (NSF) grant to advance the science of additive nanomanufacturing of multifunctional materials and hybrid structures.

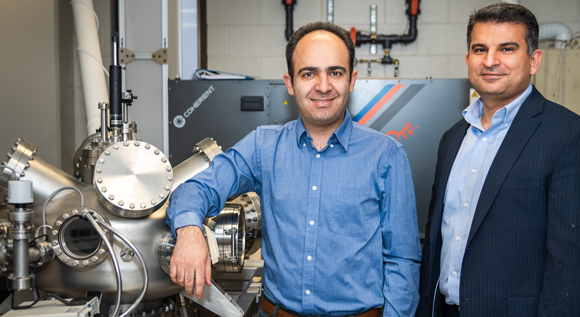

The project is led by Masoud Mahjouri-Samani, Assistant Professor of Electrical And Computer Engineering, and Nima Shamsaei, Director of NCAME. The grant will support research to develop an additive nanomanufacturing platform capable of producing multifunctional nanoparticles on-demand to produce durable hybrid structures.

The researchers explain that the Additive Manufacturing of nano-scale multifunctional materials is challenging because of minimal source materials and inadequate fabrication systems. As project leader, Mahjouri-Samani plans to generate a stream of multifunctional materials, sinter them on a submicroscopic scale using laser technology and study their behaviours on various additively manufacturedsurfaces.

According to the researchers, one of the challenges of the project will be to ensure the robustness and long-term functionality of these materials. Shamsaei will reportedly lend his expertise by evaluating the durability and structural integrity of the additively manufactured hybrid structures.

“Today, Additive Manufacturing is mainly focused on metallic and structural components, which are not functional materials,” stated Mahjouri-Samani said. “What we proposed here is to combine our knowledge of Additive Manufacturing with a variety of multifunctional materials and, for the first time, create multifunctional devices that can be printed on any conformal surface. We are hoping this technique can revolutionise the way we are printing multifunctional and electronic devices.”

Shamsaei commented, “We are definitely excited about having this technology and research at Auburn. At our Additive Manufacturing centre, most of our capabilities lie in fabricating metallic materials with micro-level accuracy. This research will be a new addition not only to our centre but also to the field of Additive Manufacturing.”