Nanoscale Additive Manufacturing offers structural protection for satellites, drones, and microelectronics

November 25, 2022

Researchers from Stanford University, California, USA, have designed a new metal/polymer composite for nanoscale Additive Manufacturing capable of absorbing twice the energy of materials with a similar density. This composite could be used to create lightweight, protective lattices for parts with fragile geometries, such as small pieces of satellites and drones, or microelectronics.

“There’s a lot of interest right now in designing different types of 3D structures for mechanical performance,” stated Wendy Gu, an assistant professor of mechanical engineering and a corresponding author on the paper. “What we’ve done on top of that is develop a material that is really good at resisting forces, so it’s not just the 3D structure, but also the material that provides very good protection.”

To design a better material for Additive Manufacturing, Gu and her fellow researchers incorporated metal nanoclusters into their feedstock. The researchers are manufacturing via two-photon lithography AM, where the feedstock is hardened through a chemical reaction initiated by laser light. Research found that the nanoclusters jump-started this hardening, resulting in a polymer/metal composite.

“The nanoclusters have very good properties for taking in the laser light, and then converting that to a chemical reaction,” Gu added. “And they’re able to do this with several classes of polymers, so they’re even more versatile than I expected.”

The researchers combined these metal nanoclusters with commonly used AM polymers, including acrylates, epoxies, and proteins. The nanoclusters also helped speed up the build process; by combining the nanoclusters with proteins, for example, the Stanford researchers were able to additively manufacture at a rate of 100 mm per second, about 100 times faster than had previously been achieved in nanoscale protein Additive Manufacturing.

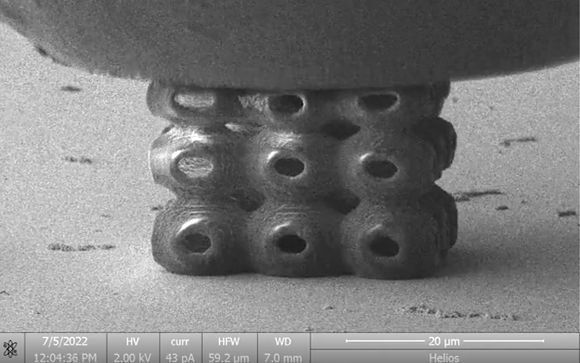

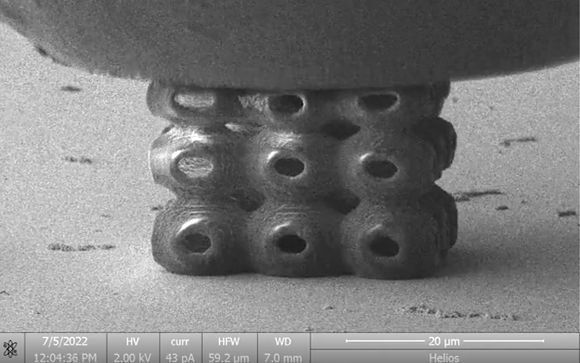

The researchers tested their new composite with several different lattice structures, prioritising the ability to carry a heavy load in some, and the ability to absorb an impact in others. With the metal/polymer composite, all the structures reportedly demonstrated a good combination of energy absorption, strength, and recoverability.

Gu concluded, “The lattice structure certainly matters, but what we’re showing here is that if the material it’s made out of is optimised, that’s more important for performance. You don’t have to worry about exactly what the 3D structure is if you have the right materials to print with.”

The paper, ‘Mechanical nanolattices printed using nanocluster-based photoresists’, was published in Science and is available here.