MSC’s new generative AM design solution reduces AM processes by 80%

November 20, 2019

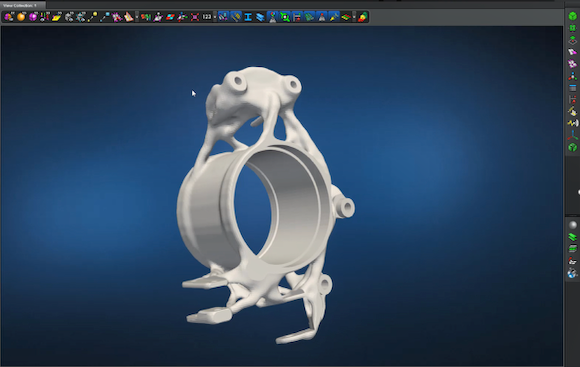

MSC’s new software is said to produce a part design that is ready for Additive Manufacturing within a few hours – a fraction of the time usually required (Courtesy MSC Software)

MSC Software Corporation (MSC), recently acquired by Hexagon, has announced the launch of its MSC Apex Generative Design, a new design optimisation solution that improves quality through automation of design processes with embedded manufacturing knowledge.

MSC Apex Generative Design aims to improve productivity by up to 80% compared to classic topology optimisation. The software produces a part design that is ready for Additive Manufacturing within a few hours – a fraction of time usually required – making reliable AM more cost efficient and accessible.

“New design freedoms in Additive Manufacturing request new-generation software solutions, which take full advantage of the new DfAM [design for Additive Manufacturing] possibilities,” stated Dr Thomas Reiher, Director of Generative Design. “We make the generative design process smarter by producing design candidates that both satisfy the engineering criteria and look as the designer intended when 3D printed.”

Conventional topology optimisation workflows require manual work and multiple tools to achieve production-ready results, which can lead to information loss as data is converted. MSC Apex integrates all relevant steps within one Computer Aided Engineering (CAE) environment to improve productivity with a single user experience from design to additive manufacturing preparation.

The design process is workflow-oriented, providing easy and fast model setup from existing geometries or mesh in common CAD, STL, or MSC Nastran BDF formats. Designers can find optimised design candidates and perform design validation within the same CAE environment, simplifying the work process and reducing design iterations dramatically. The result is a fully integrated, automated optimisation process in which compatibility for previous and subsequent operations plays a vital role. This unique capability implies the conversion from the CAE mesh to CAD with no manual reconstruction of geometry, considerably simplifying the work process for designers.

The MSC solution combines print-ready geometries with robust metal (Simufact) and polymer (Digimat) build process simulation from Hexagon’s Additive Manufacturing portfolio. Designers only generate part designs that can be successfully manufactured using their chosen material and print process to eliminate costly prototyping.

Hugues Jeancolas, VP Product Management, commented, “Additive Manufacturing promises innovation and manufacturing productivity advances. But to truly transform, the new technologies require automated design workflows with embedded process knowledge. We are integrating our structural analysis, design optimisation, and manufacturing simulation solutions to optimise and validate designs for additive processes before a single part is printed.”

www.mscsoftware.com/product/msc-apex-generative-design