Mitsubishi Power establishes licensing agreement with Aubert & Duval as it nears launch of new AM business

November 30, 2020

Mitsubishi Power, Ltd., a subsidiary of Mitsubishi Heavy Industries (MHI) Group, Yokohama, Japan, and Aubert & Duval, a subsidiary of the High Performance Alloys Division of the Eramet group, based in Paris, France, have announced a licensing agreement for the production and distribution of metal powders used for Additive Manufacturing.

The agreement is said to pave the way for the full-scale launch of Mitsubishi Power’s AM business, which follows the recent creation of an AM-Zone® at its Hitachi Works in Ibaraki Prefecture to serve as a development and manufacturing base for the company’s Additive Manufacturing business.

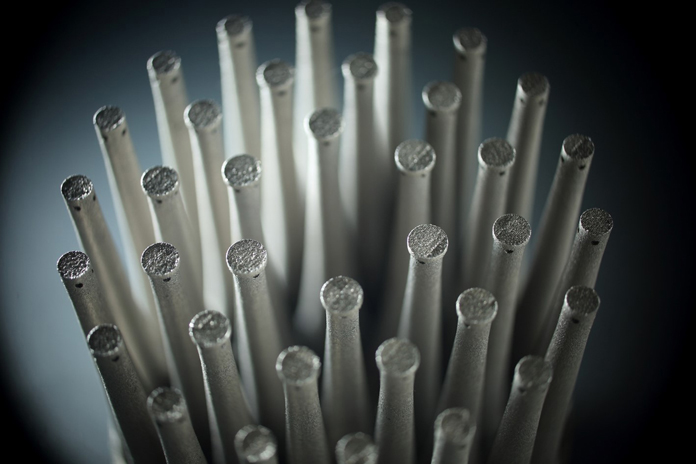

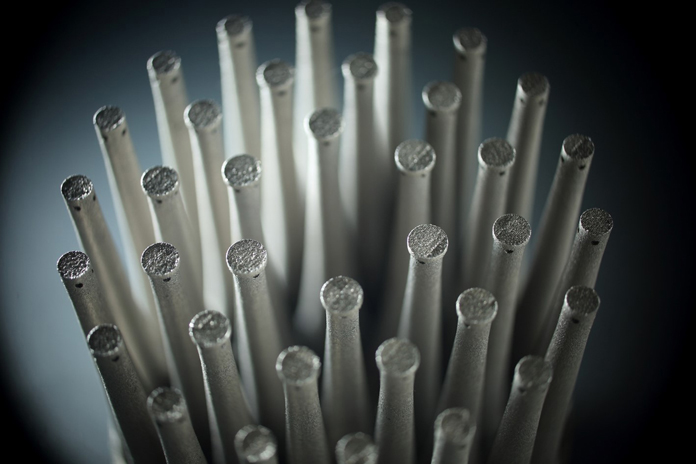

The new facility is equipped with powder manufacturing equipment and metal AM machines, and is said to be capable of fully integrated production – from the development of powder and wire materials to metal AM and product finishing.

Mitsubishi Power explains that it possesses proprietary material technologies in metal AM, and can optimally prepare raw materials for each application required. It also has technologies that significantly enhance the performance of powder manufacturing equipment. This is achieved by incorporating the company’s specially developed high-performance gas nozzles into the gas atomisation system that produces metal powder materials by atomising inert gas into vacuum-fused metals.

Under the new agreement, Aubert & Duval’s know-how in the composition and manufacturing of powders for AM applications will be combined with Mitsubishi Power’s proprietary technologies to enable the provision of powders optimally suited to metal Additive Manufacturing. Along with the creation of the AM-Zone, Mitsubishi Power will become involved in all aspects of metal AM processing, from material development to final product manufacture.