Mitsubishi Electric reveals new Dot Forming Technology for metal Additive Manufacturing

October 26, 2018

Mitsubishi Electric will exhibit a metal Additive Manufacturing machine incorporating its DFT technology at the 29th Japan International Machine Tool Fair (Courtesy Mitsubishi Electric)

Mitsubishi Electric Corporation, Tokyo, Japan, has reportedly developed a new technology for high-precision metal Additive Manufacturing. Known as ‘Dot Forming Technology’ (DFT), the process combines laser, CNC and computer aided manufacturing (CAM).

According to the company, DFT produces metal components with few voids at high speed, employing a laser wire Directed Energy Deposition (DED) process which fuses materials as they are deposited. The company stated that it believes this new process has the potential to raise productivity in a wide range of applications, including the near net shape manufacture of aircraft and automobile parts, and build-up repairs.

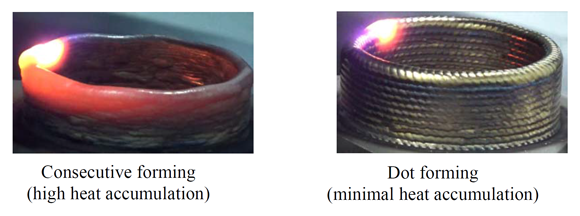

Improving shape accuracy with dot forming

A comparison between part deformation in consecutive forming and dot forming technologies (Courtesy Mitsubishi Electric)

A key focus of DFT’s development has reportedly been on avoiding the part deformation which can occur during DED. During DED, heat generated by a laser and heat from the just-deposited material are transferred to the deposition base. If the laser is continuously irradiated, the temperature of the deposition base rises, and new molten material added to this base can take more time to solidify, causing the shape of the part to collapse under its own weight.

To prevent this outcome, Mitsubishi Electric stated that its new technology uses a unique pulsed lase and CNC technology with minimised heat input, to help ensure adequate cooling time. Further, the new DFT technology also synchronously controls the supply of wire feedstock and shield gas, and the position and moving speed of the laser irradiation point.

This means high temperatures are limited to a point-like narrow area, making it possible for the antioxidant action of the shield gas to spread across the entire high-heat area, suppressing oxidation. The production of complex parts is further supported by the use of special-purpose CAM, which automatically generates forming paths corresponding to the Dot Forming Technology.

Mitsubishi Electric will exhibit a metal Additive Manufacturing machine incorporating its DFT technology at the 29th Japan International Machine Tool Fair (JIMTOF2018), set to be held at the Tokyo Big Sight exhibition complex from November 1-6, 2018. It expects to launch a commercial version of the system in 2021.