Metal Powder Emergence offers metal powders and consultancy services

March 9, 2022

Metal Powder Emergence Ltd (MPE), headquartered in London, UK, is a recently established business providing gas atomised metal powders for Additive Manufacturing, as well as Metal Injection Moulding (MIM), Hot Isostatic Pressing (HIP) and cold/thermal spray applications.

Before founding MPE, Dr Gordon Kerr, the company’s CEO, spent ten years at Phoenix Scientific Industries (PSI) where he worked with customers and collaborators developing VIM gas atomised powders for a range of applications and sectors.

“My experience over the past ten years has shown that it’s possible to supply high-quality additive metal powders at a cost which is more closely aligned with the client’s needs,” stated Kerr.

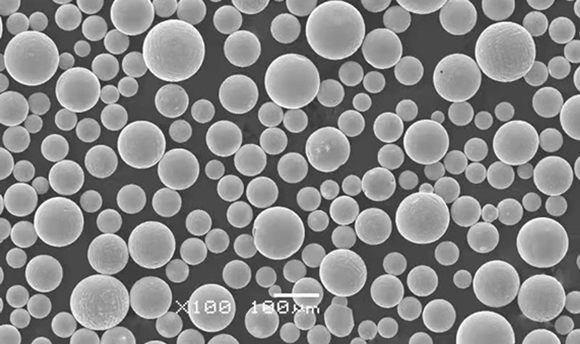

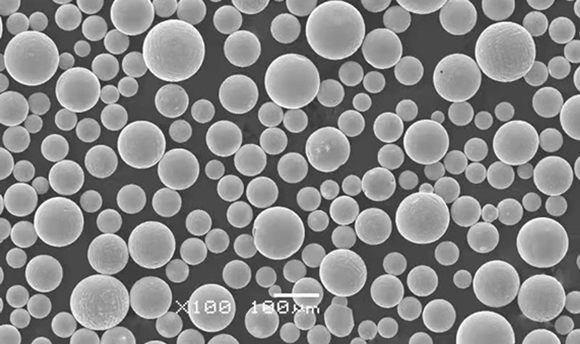

MPE is currently working with a key business partner to provide cost-effective, high-quality metal powders which are manufactured in accordance with ISO 9001. The powders are melted under a vacuum, which provides clean, free-flowing powders with high sphericity, vital for many AM processes.

“Generally, lead times are shorter compared to many other powder providers. All powders are re-qualified using 3rd party independent UK analytical service test houses which are also ISO 9001 compliant,” added Kerr.

Established alloy powders based on aluminium, cobalt chrome, copper, titanium, nickel superalloys, stainless steels (316L, 17-4PH) are available, as well as the supply of bespoke novel alloy compositions. Technical and manufacturing consultancy is offered to assist in the development of powder alloy compositions tailored to meet clients’ needs.

With a PhD in Chemistry from Heriot-Watt University in Scotland, Kerr has played a key role in European and UK funded projects with Innovate UK, Faraday and NATEP/ATI. He has previously held Managing Director positions and delivered growth within high-technology businesses, developing and implementing strategies to address various market and customer needs, as well as driving teams to common goals.

MPE can take a product from R&D scale to full-scale production manufacturing utilising marketing and sales expertise in order to meet a range of market needs. Kerr is primarily focused on developing novel AM materials for applications such as nanotechnology, responsive and smart materials for markets such as aerospace, marine, battery applications and space exploration.

MPE recently collaborated on new projects and applied for UK grant funding with a leading UK University in Materials Science and two well-established UK organisations.