Metal additively manufactured Stealth Key wins first prize in the Purmundus Challenge

November 22, 2019

The winners of the Purmundus Challenge were announced at Formnext 2019, Frankfurt, Germany, with Dr Alejandro Ojeda from UrbanAlps AG taking first prize with his project ‘Stealth Key’.

Organised by cirp GmbH, the Purmundus Challenge, is sponsored by Germany’s VDMA and this year included thirty-eight finalists in the competition.

The metal-based winning parts were as follows:

First Prize of Purmundus Challenge

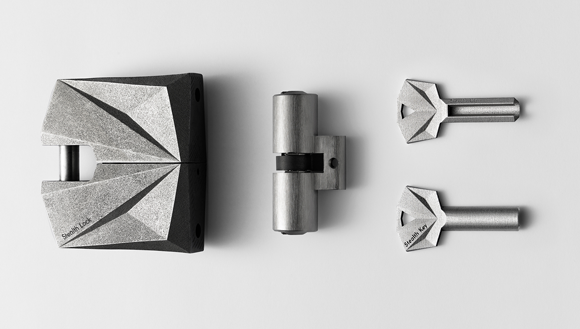

Dr Alejandro Ojeda at UrbanAlps AG developed the Stealth Key using industrial metal Additive Manufacturing technologies. This range of keys was designed to overcome the security threat posed by the availability of commercial AM technologies which might be used to scan and duplicate door keys.

The Stealth Key replaces the conventional key design, made out of sheet metal with a visible ‘code’ shape, with a new design in which the code is hidden within a superalloy cylinder, ensuring the key cannot be photographed or scanned.

Third Prize of Purmundus Challenge

Dr Paul Schüler and Andreas Krüger of CellCore GmbH, in collaboration with SLM Solutions Group AG, developed a monolithic and multi-functional rocket engine concept to demonstrate the potential and benefits of metal L-PBF Additive Manufacturing. The rocket engine demonstrator, produced in IN718 on an SLM 280 machine, combines a fuel inlet, injection head, thrust chamber and innovative structural cooling concept in one integrated design.

The core element of the demonstration piece is the functionally optimized lattice structure integrated into the chamber wall, which in addition to providing the necessary stability, but also offers opportunities for cooling by efficiently conducting heat away from the thrust chamber’s internal wall by actively circulating liquid hydrogen.

This structural cooling is said to offer a significant improvement over conventional approaches such as concentric milled cooling channels. It also reportedly offers an ideal ratio between stability and the amount of material used, and has low flow resistance combined with a large reaction surface.

The Audience Award of Purmundus Challenge

Byron Blakey-Milner of NMU Eco-Car, based out of Nelson Mandela University, South Africa, designed and produced an additively manufactured Ti-6Al-4V mountain bike frame, produced by L-PBF on the Aeroswift large-scale Additive Manufacturing machine. Due to the very high cost of top of the range mountain bike components, the company believes this design could compete economically with high-end carbon fibre designs.

Using topology optimisation, the designer was able to increase the frame’s competitiveness with regard to weight and stiffness, without being limited to the single/split draw mould constraints of carbon bike frames.