Metal Additive Manufacturing of structures “smaller than a speck of dust”

February 19, 2018

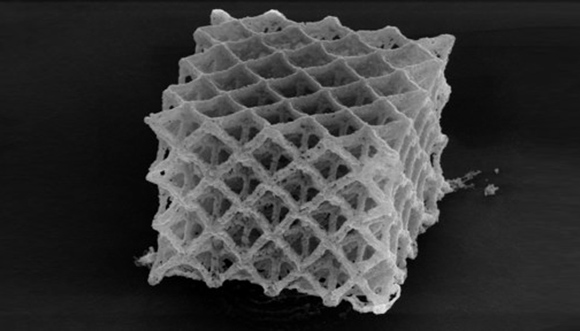

The final metal additively manufactured nanostructure was reported to be smaller than a speck of dust (Courtesy Caltech)

A group of scientists at the California Institute of Technology (Caltech), California, USA, have reportedly developed a new process which enables the metal Additive Manufacturing of structures smaller than a human hair and invisible to the naked eye. In a paper published in Nature Communications, ‘Additive Manufacturing of 3D Nano-Architected Metals’, the group stated that the process could be scaled up for use in a wide variety of applications, including the production of tiny medical implants, ultralightweight aircraft components 3D logic circuits on computer chips.

The principal researchers on the project were Julia Greer, Professor of Materials Science, Mechanics and Medical Engineering at Caltech’s Division of Engineering and Applied Science, and graduate student Andrey Vyatskikh. While Greer has previously additively manufactured nanostructures from materials such as ceramics, polymers and organic compounds, this is the first time the team has successfully applied her nanoscale AM technique to metals.

Greer’s process works by lasing a liquid or resin in specific locations with just two photons, in a process called ‘two-photon lithography’. This generates enough energy to harden liquid polymers into solids, but is not strong enough to fuse metal. “Metals don’t respond to light in the same way as the polymer resins that we use to manufacture structures at the nanoscale,” explained Greer. “There’s a chemical reaction that gets triggered when light interacts with a polymer that enables it to harden and then form into a particular shape. In a metal, this process is fundamentally impossible.”

The solution, developed by Vyatskikh, is to use organic ligands (molecules with the ability to bind to trace metals in the aquatic dissolved phase) to create a resin comprising primarily of polymer, but ‘carrying with it’ a metal which can then be additively manufactured. Vyatskikh’s technique bonds nickel with organic molecules to create a liquid ‘syrup’ which was then lased with a two-photon laser to build a structure according to a CAD design.

Under the laser, the organic molecules hardened into ‘building blocks’ for the structure, which the nickel atoms were incorporated into. The result was an additively manufactured nanostructure comprising a blend of metal ions and nonmetal organic molecules.

Vyatskikh then heated the nanostructure slowly in a vacuum to 1000°C – below the melting point of nickel, but hot enough to vaporise the organic materials in the structure and leave only the metal. This heating process also resulted in fusing of the metal particles, as well as structural shrinkage of about 80%. The combination of Greer’s nanoscale AM process and the part shrinkage resulted in a final structure which was reported to be smaller than a speck of dust.

“In the structure we built for the paper, the diameter of the metal beams in the printed part is roughly 1/1000th the size of the tip of a sewing needle,” stated Vyatskikh. Greer and Vyatskikh report that the process requires some refinement, with the initial structures showing some voids left behind by the vaporised organic material as well as some minor impurities. The process also requires scaling up to be suitable for many of its planned applications.

The research team stated that it is interested in expanding adapting the process to work with other metals, such as tungsten and titanium, which are challenging to produce at very small scales. Co-authors on the paper include Akira Kudo, Caltech Resnick Sustainability Institute postdoctoral scholar in Applied Physics and Materials Science, Carlos Portela, graduate student in Mechanical Engineering, Stéphane Delalande, of the Centre Technique de Vélizy, France, and Xuan Zhang of Tsinghua University, China. Research funding was provided by the US Department of Defense.