Additively manufactured heat exchangers enable SOFC operation in ships

July 28, 2022

A research project to convert diesel into a fuel gas for solid oxide fuel cells (SOFC), and the coupling with an energy storage system for operation on ships, has been successfully completed under the lead of OWI Science for Fuels gGmbH, Aachen, Germany. Known as MultiSchIBZ, the researchers goal was to produce on-board power for ships at sea and at berth, operating with low carbon dioxide and other pollutant emissions.

The team had to overcome a number of challenges including high gas temperatures of up to 900°C and a limited installation space, as well as the need for low maintenance and to meet high safety requirements for on-board operation.

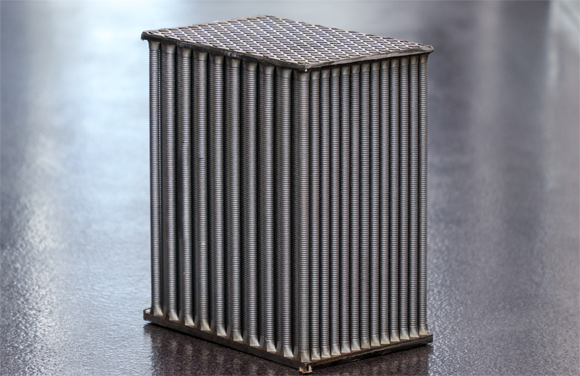

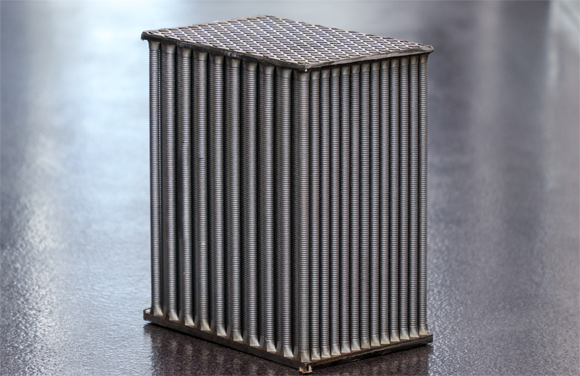

The system required the production of heat exchangers, but the high demands of operation could not be met with conventional designs, as current tube recuperators are too large and plate recuperators do not meet the high safety requirements.

The team turned to metal Additive Manufacturing, with a new tube bundle and plate recuperator designed and manufactured by Rosswag Engineering, based in Pfinztal, Germany, in collaboration with the Institute of Thermodynamics at the University of Hanover and Hülsenbusch Apparatebau GmbH, Kempen.

Using Laser Beam Powder Bed Fusion (PBF-LB), along with the qualification of high-temperature resistant steel AlSl309, enabled the heat exchangers meet the high-performance demands. The new heat exchangers are also reputed to meet the high safety requirements for use on ships.