MELD to offer unique metal Additive Manufacturing process

April 18, 2018

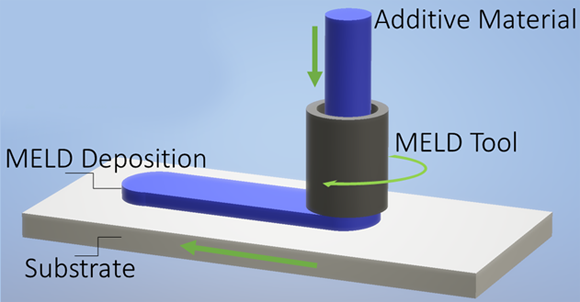

MELD is a solid-state process which can be used to manufacture parts in a wide range of materials, including metal powders and rods (Courtesy MELD Manufacturing)

Aeroprobe Corporation, Christiansburg, Virginia, USA, states that it is to commercialise its patented MELD manufacturing process after over a decade of research and development. The commercialisation process will include the establishment of a spin-off venture, MELD Manufacturing Corporation.

The company holds more than a dozen patents for MELD, a solid-state process which can be used to manufacture parts in a wide range of materials, including metal powders and rods. It can also be used with metal chips generated as the waste material in other manufacturing processes.

“Our technology is truly unique,” stated Nanci Hardwick, MELD CEO. “We identified an area in the Additive Manufacturing industry that could be improved upon and put a lot of time and effort into making it happen. The MELD process is a game changer in the Additive Manufacturing field and beyond.”

Chase Cox, Additive Manufacturing Manager at MELD, explained, “What sets us apart from other technologies is that we aren’t melting. When you melt, you introduce weakness and other issues. By taking the material up to a point where it is malleable but not melted, we end up with properties that meet or exceed similar processes and, in some cases, even those of the original material.”

While there are other Additive Manufacturing processes which do not require melting of the feedstock material, MELD is said to be further differentiated by the fact that it is an open atmosphere process, meaning that no special chambers or vacuums are needed to operate a MELD machine.

“Being open atmosphere means less equipment and fewer headaches,” continued Cox. “From a manufacturing standpoint, it also means that MELD isn’t limited in the size of the parts it can make. Compared to similar processes, we can make parts that are not only bigger, but also superior in quality and material options.”

As well as being used to additively manufacture components, the MELD process can be used to repair, coat and join materials, and could make it possible to weld previously unweldable materials. “I was very excited the first time I saw the MELD technology,” commented Paul Allison, Assistant Professor at the University of Alabama, which has a MELD machine installed on its campus.

“It was and still is obvious that MELD provides a breakthrough in manufacturing technology that overcomes the technical barriers of fusion-based processes. That innovation is why I was eager to purchase a MELD machine and to work with the MELD team to pioneer research for this technology.”

The MELD process is reported to deposit material at least ten times faster than fusion-based metal AM processes. It is expected to find application in a range of areas including the automotive, aerospace, defence and turbomachinery industries. MELD Manufacturing Corporation will offer machine sales in addition to contract manufacturing and consulting services.