Mazak to showcase its hybrid Additive Manufacturing system at MT360

May 14, 2019

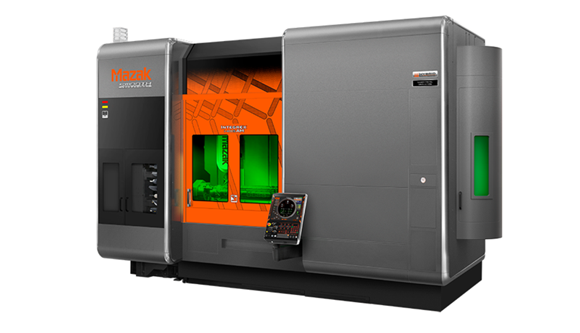

Mazak will showcase its hybrid multi-tasking systems at the MT360 conference (Courtesy Mazak)

Mazak Corporation, the US division of Japan’s Yamazaki Mazak, headquartered in Florence, Kentucky, USA, has reported that it will be showcasing key technologies, including its HYBRID Multi-Tasking Additive Manufacturing system, at the MT360 event in Santa Clara, California, USA, June 18–20, 2019.

MT360 is said to be a one-of-a-kind education and networking event, bringing together the best-of-the-best in manufacturing and technology. In addition to its hybrid AM system, Mazak will present its Smooth Technology, a comprehensive suite of digital solutions and network connectivity options. Together, it will demonstrate how these technologies help manufacturers achieve full digital connectivity for process monitoring and optimisation.

To provide manufacturers with true, single-setup part processing capability, Mazak integrates advanced Additive Manufacturing technology into traditional multi-tasking and full simultaneous five-axis subtractive machine tools. Technologies such as wire arc Additive Manufacturing and multi-laser metal deposition are used on these hybrid systems.