Markforged releases Eiger Fleet distributed manufacturing software to scale AM

September 15, 2021

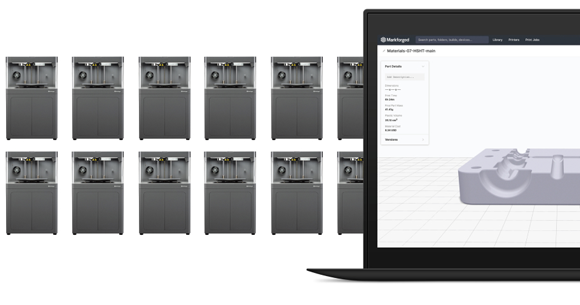

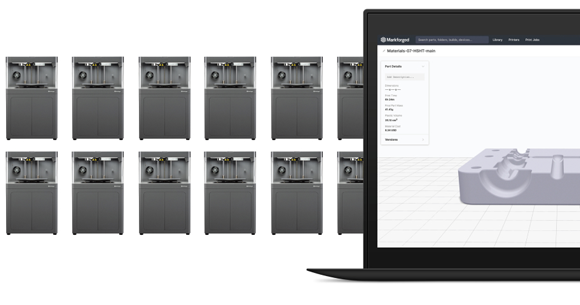

Markforged, Watertown, Massachusetts, USA, showcased its Eiger Fleet cloud-based software solution at the recent RAPID + TCT 2021 show in Chicago, Illinois, USA. Through Eiger Fleet, Markforged aims to transform Additive Manufacturing from small-scale operations to large, globally connected, distributed manufacturing by giving organisations a secure, centralised source of control over Markforged AM machines, users and part production.

The software is designed to help manufacturers adopt AM technologies into more traditional workflows. For organisations looking to scale AM capabilities, Eiger Fleet offers enterprise-level features to manage users, devices and data with greater control and efficiency to additively manufacture parts on demand at the point of need.

Vestas Wind Systems A/S, a global provider of sustainable energy solutions, utilises Eiger Fleet to manage the production of parts and tools for its global fleet of wind turbines on Markforged AM machines.

“Over the past several years, Direct Digital Manufacturing (DDM) has evolved at Vestas to connect our factories around the world to support agile production of parts and tools on demand,” stated Jeremy Haight, Principal Engineer, Industrial Automation and Additive Manufacturing at Vestas. “We depend on the Markforged platform with Eiger Fleet and Blacksmith to provide the centralised control, enterprise resource planning (ERP), asset management, and other system integration and print analysis for industrial-grade Additive Manufacturing that our global business needs.”

With Eiger Fleet, Vestas has enabled its teams to order a part from their ERP system, creating a digitised Kanban inventory system, and have that part produced by the nearest Markforged AM machine with the click of a button. Vestas is also said to be cutting lead time and costs with the software. One example identified by Vestas is a marking tool critical for proper assembly of blades on its wind turbines. Previously, it required a lead time of three weeks and cost thousands of dollars – now, it requires only three days from design to installation, and costs under $100.

Eiger Fleet is designed to enable customers to:

- Control which part, build, devices, print operations and data are accessible to users according to job responsibilities and privileges by leveraging role-based access control (RBAC)

- Provide simpler user and administrator experience through SAML Single Sign-On (SSO), where automated account provisioning reduces IT costs, and easily and consistently enforces strong access policies with identity protection

- Connect, simplify and automate workflows with Eiger API, connecting Additive Manufacturing processes to existing enterprise software systems

- Seamlessly manage entire digital inventory of parts, leveraging batch operations and organisation-wide presets

- Easily track, analyse and share key performance indicators of time and cost savings from AM

“Additive technology is transforming manufacturing around the world,” stated David Benhaim, CTO and co-founder of Markforged. “Eiger Fleet fuels the expansion of Additive Manufacturing by giving our customers the right set of control and management tools that address the concerns of security, quality management, auditing or user error. Our customers are able to grow their operations with the right level of control over quality and process. Eiger Fleet is setting the pace for what’s possible in the future of manufacturing, through cloud-enabled distributed manufacturing.”