LLNL investigates microcrack formation in tungsten Additive Manufacturing

August 26, 2020

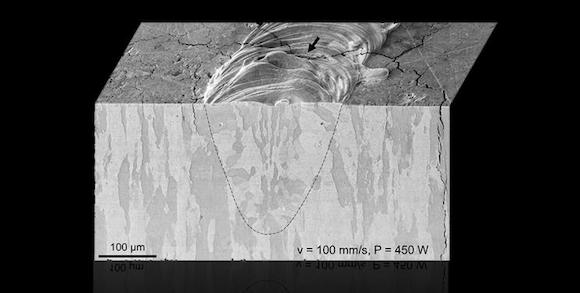

By combining simulations with high-speed videos taken during the PBF-LB build process, LLNL scientists were able to visualise the ductile-to-brittle transition in tungsten in real-time, allowing them to observe how microcracks initiated and spread in the metal (Courtesy Lawrence Livermore National Laboratory)

Lawrence Livermore National Laboratory (LLNL), Livermore, California, USA, has conducted a study using thermomechanical simulations and high-speed videos, taken during the Laser Beam Powder Bed Fusion (PBF-LB) metal Additive Manufacturing process, to characterise how and why microcracks form in the AM of tungsten.

Tungsten has the highest melting and boiling points of all known elements, making it a popular choice for applications involving extreme temperatures, including lightbulb filaments, arc welding, radiation shielding and, more recently, as a plasma-facing material in fusion reactors such as the ITER Tokamak.

However, tungsten’s inherent brittleness, and the microcracking that occurs within the material during PBF-LB AM, currently pose challenges to its widespread adoption.

Previous research into microcracking in tungsten has been limited to examining cracks post-build, but observing the build process in real-time allowed LLNL’s scientists to observe how microcracks initiated and spread as the metal heated and cooled.

Thanks to this real-time perspective on the process, the team was able to correlate the microcracking phenomenon with variables such as residual stress, strain rate and temperature, and confirm that the ductile-to-brittle (DTB) transformation of the material was the cause of the cracking.

The LLNL researches stated that the study, recently published in the journal Acta Materialia, uncovered the fundamental mechanisms behind cracking in AM tungsten and set a baseline for future efforts to produce crack-free parts from the metal.

“Because of its unique properties, tungsten has played a significant role in mission-specific applications for the Department of Energy and Department of Defense,” stated co-principal investigator Manyalibo Matthews. “This work helps pave the way toward new Additive Manufacturing processing territory for tungsten that can have significant impact to these missions.”

Through experimental observations and computational modelling performed using LLNL’s Diablo finite element code, the researchers found that microcracking in tungsten occurs in a small window between 450 and 650 degrees Kelvin and is dependent on strain rate, which is directly influenced by process parameters. They were also able to correlate the size of the crack-affected area and crack network morphology to local residual stresses.

Lawrence Fellow Bey Vrancken, the paper’s lead author and co-principal investigator, designed and performed the experiments and also conducted most of the data analysis. The work was funded through the Laboratory Directed Research and Development programme, and LLNL engineer Rishi Ganeriwala performed the finite element model simulations and co-authored the paper

“I had hypothesised that there would be a delay in the cracking for tungsten, but the results greatly exceeded my expectations,” Vrancken explained. “The thermomechanical model provided an explanation for all our experimental observations, and both were detailed enough to capture the strain rate dependence of the DBT. With this method, we have an excellent tool to determine the most effective strategies to eliminate cracking during the LPBF of tungsten.”

The work is reported to provide a detailed, fundamental understanding of the influence of process parameters and melt geometry on crack formation and to show the impact material composition and preheating have on the structural integrity of parts printed with tungsten.

The team concluded that the addition of certain alloy elements could help reduce the DBT transition and strengthen the metal, while preheating could help mitigate microcracking. The team is using the results to evaluate existing crack-mitigation techniques, such as process and alloy modifications.

The findings, along with the diagnostics developed for the study, will be crucial to LLNL’s ultimate goal of additively manufacturing crack-free tungsten parts that can withstand extreme environments.