Link3D introduces additive material recommendation system

February 5, 2019

Link3D Material Recommendation System includes a database of over 1000 materials across over 500 AM machines

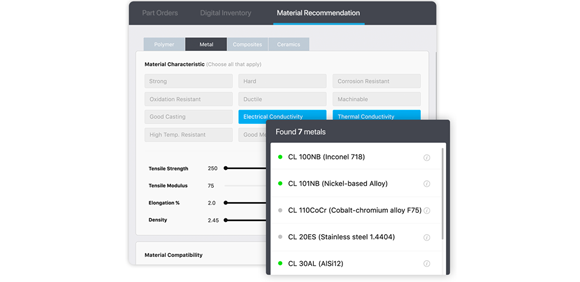

Link3D, headquartered in New York City, USA, has announced the launch of its Additive Material Recommendation System (AMRS), designed to be integrated in the existing Link3D industrial Additive Manufacturing workflow solution to simplify material selection processes. AMRS will help engineers select the most appropriate materials based on qualitative and quantitative specifications for production, providing an understanding of material performance across over 1000 materials and over 500 AM machines.

The Link3D platform is designed to enable organisations streamline their Additive Manufacturing supply chains. This begins from order submission, auto-quoting, production planning and scheduling, post-processing, quality inspection, logistics management across internal and distributed supplier network.

AMRS offers an intelligent recommendation system that allows new-to-additive engineers select a material most fitting for their AM builds through an intuitive filtering system. Engineers with an existing understanding of AM materials can easily access technical data for quicker decision-making without having to manually review material manufacturer’s spec sheets.

As a result, engineers can design and produce higher quality, more economical, and functional products. Engineers can narrow down material selections by filtering qualitative key characteristics and technical material property ranges:

By Qualitative Material Characteristics, examples for

- Polymer key characteristics: rigid, strong, tough, accurate, biocompatible, durable, high temperature resistant and rubber-like specifications

- Metal key characteristics: corrosion resistant, oxidation resistant, biocompatible, high temperature resistant, electrical conductivity, ductile and thermal conductivity specifications

- Others: Hardness options, Material colours

By Technical Material Properties

Tensile strength (Mpa), tensile modulus (Gpa), elongation at break (%), material density and hardness

By Material Manufacturer:

EOS, Concept Laser, Trumpf, Stratasys, Carbon, Renishaw, HP, Additive Industries, etc.

“One of the major recurrent hurdles we’re hearing from our customers is how to accelerate the adoption of Additive Manufacturing within their own organisation”, explains Renaud Vasseur, VP of Business Development & Sales at Link3D. “We are thrilled that Link3D is introducing an Additive Manufacturing recommendation system that will not only help engineers achieve their design goals, but also increase overall understanding of the additive manufacturing capabilities and workflows.”