Link3D enables Argentinian orthopaedic implant maker’s first step into metal AM

February 21, 2018

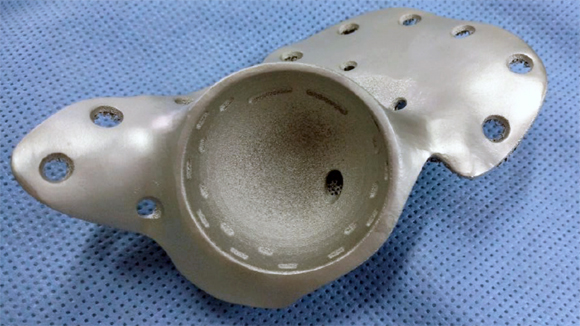

Imeco’s first AM hip replacement was developed for a patient with a special medical condition (Courtesy Link3D)

Argentinian orthopaedic implant company Imeco S.A. reports that it has recently installed its first metal additively manufactured hip replacement. The company first discovered the potential of metal AM orthopaedic implants at a 2014 US trade show, but stated that it didn’t begin actively pursuing the technology until roughly six months before completing its first implant.

This first AM hip replacement by the company was developed for a patient with a special medical condition. According to Imeco, 10-15% of all orthopaedic conditions could benefit from additively manufactured implants. However, the cost of metal AM technologies and the knowledge gap between conventional medical manufacturing and medical Additive Manufacturing pose significant obstacles for some smaller medical companies.

Dr Santiago Pierce, Imeco’s Head of R&D, explains, “Even though we have a lot of articular orthopaedic design experiences for special conditions, we don’t have partners to teach us 3D printing and manufacturing. It is not cost-effective to purchase machines worth upwards of $1-2 million dollars when we are at an experimental phase.”

The final metal additively manufactured hip implant was produced by CEIT-Ke, Slovakia (Courtesy Link3D)

The ideal solution, therefore, was to outsource the project to an Additive Manufacturing service provider. Having spoken with Link3D representative Christian Rice, Imeco was subsequently able to use Link3D’s On Demand™, a secure platform which enables its users to search and connect with a global network of Additive Manufacturing solutions providers, to compare qualified and certified service bureaus for the AM of medical implants.

Through the On Demand platform, Dr Pierce made contact with CEIT-Ke, a biomedical engineering service bureau based in Slovakia. “Besides a competitive price, it was Bruno [Goban, CEIT-Ke representative]’s responsiveness and complete breadth of knowledge on the subject matter.”

“Link3D provided Imeco with exactly what we needed to propel forward with 3D printing,” he added. “To complete such a surgery is a great success because it truly symbolises a massive shift from forty years of traditional medical manufacturing – like CNC and forging – to the era of Additive Manufacturing.”