Linde launches advanced gas delivery system to control Cold Spray Additive Manufacturing

March 28, 2023

Industrial gases and engineering company Linde has announced the launch of Linspray® Connect, a new gas delivery system for Cold Spray Additive Manufacturing. Developed in collaboration with Germany’s Impact Innovations, the solution is intended to enhance the reliability and safety of the Cold Spray AM process.

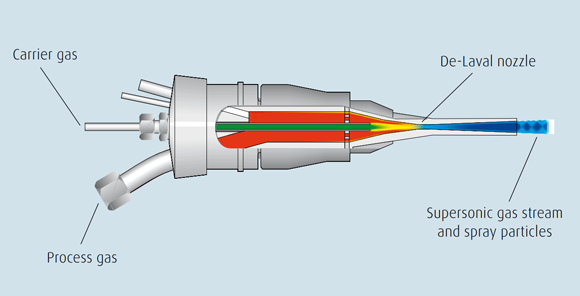

During the Cold Spray AM process, metal powders of between 5-50 microns are propelled onto a substrate using high-pressure gases. The powder, which starts at ambient temperatures, is placed in a nitrogen or helium gas stream which is then heated and accelerated through a supersonic nozzle at speeds between 500-1200 meters per second. The temperature of the metal powder remains far below its melting point, ensuring the metal particles stay in their solid state, retain their unique properties and remain oxidation resistant. The coating created via this process is ductile, which also prevents any risk of embrittlement under stress.

The manufacturing of coated products is heavily dependent on a number of factors, including the supply of high purity gases and a stable and reliable gas flow with minimal pressure variation – all of which must be within a specified temperature range of up to 1100°C. Rapid temperature changes can damage both the gas heater and the laval nozzle at the tip of the spray gun. Constant, reliable pressure is needed to ensure a smooth gas flow, which will ultimately influence the coating quality, with any fluctuations potentially having a negative impact on delivering a uniform coating and overall product quality.

The design of the Linspray Connect is said to not only ensure the delivery of a reliable, stable and high-quality gas flow with minimal variation, but it also enables the customer to monitor process parameters, including pressure, temperature and filling levels of the nitrogen tank. It automatically sends error messages in real time and can switch to an emergency gas supply or activate a safe shut-down of the system in case of incidents. Production volume can easily be increased or decreased as required.

These enhanced delivery capabilities are expected to result in reduced downtime as error notifications allow for proactive, preventative maintenance. It will also reduce the instances of rejects and any rework required.

“Linde has long been the backbone of high-quality gas supply for industries looking to develop products that rely on innovative coatings,” stated Paolo Kirchpfening, Global Commercialisation Manager Manufacturing Markets, Linde. “Through our collaboration with Impact Innovations, we are excited to be able to offer a new, first-of-its-kind gas delivery system that will provide manufacturers with far greater insight and control of their cold spraying process.”

Linde and Impact Innovations predict that while applications for the new gas delivery solution will be an important development for a wide range of industries requiring inductive or resistant coatings, there will be particular interest for sectors in nuclear energy (for the coating of storage and transport containers to prevent corrosion), aerospace (for repair techniques for lightweight alloy components and Additive Manufacturing of combustion chambers), cookware (for induction coatings) and automotive (for brake disc coatings to reduce emissions and thermal management for electric vehicles with hybrid heatsinks).

“We are delighted that our collaboration with Linde has resulted in what is a significant development to advance our cold spraying system,” added Leonhard Holzgassner, Technical Director & Founder, Impact Innovations. “Improving productivity, reducing costs, maintenance and energy usage are never-ending goals for manufacturing innovators, and we’re proud to say Linspray Connect in combination with our Impact EvoCSII systems are truly boosting cold spraying technology to the next level.”

Download Metal AM magazine