Linde and 3D Medlab optimise atmospheres for complex medical device structures

July 27, 2020

Industrial gas specialist Linde, Guildford, Surrey, UK, reports that it has begun a research project into how atmospheric conditions in the Additive Manufacturing process can be optimised to produce complex latticed structures for medical devices, in collaboration with medical device maker 3D Medlab, Marignane, France.

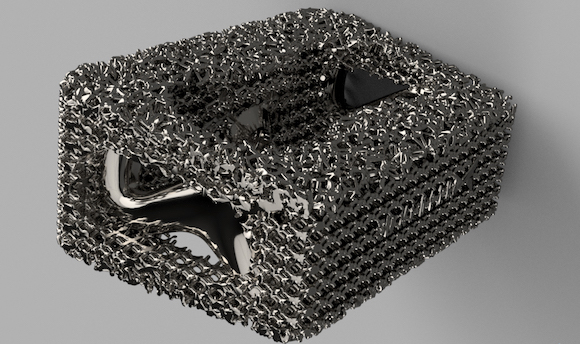

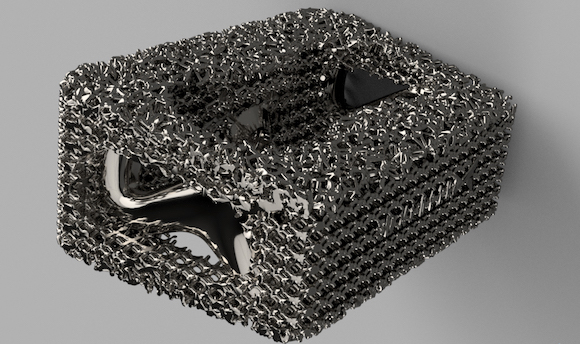

Multifaceted, latticed components aim to mimic natural human body parts and can better assimilate into the patient’s own bone and tissue structure, leading to fewer rejections and quicker healing times. Powder Bed Fusion (PBF) Additive Manufacturing has been used by a number of medical device makers to produce these structures.

However, for high-quality and repeatable parts to be possible, the atmosphere in the build chamber of an AM machine needs to be optimal and reproducible.

Linde explained that atmospheric gases play a fundamental role in the build process, and any impurities that remain in the chamber, even once purged, can have a detrimental effect on the part being manufactured. Additionally, fumes created during the production process can remain on the part, requiring post-production cleaning.

Even extremely small variations in oxygen content within the build chamber can impair the mechanical or chemical properties of metals sensitive to oxygen – such as titanium and aluminium alloys – and can affect the composition of the end product. For the Linde and 3D Medlab’s research trials, the titanium alloy used will be Ti6AI4V.

“We are proud to be collaborating with 3D Medlab on this important and forward-looking project,” stated Pierre Forêt, Senior Expert Manufacturing, Linde. “As a customer at the forefront of medical device manufacturing, anything less than optimal product outcomes is critically important to avoid, so it is testament to our gases expertise and know-how that we have been selected to partner in this endeavour.”

The atmospheric trials involve a new helium/argon gas mixture created especially by Linde for the project to make the process smoother and cleaner, along with use of Linde’s ADDvance O2 precision oxygen measuring and analysis technology, used to ensure the optimal mix of gases within the build chamber.

Along with the new gas mixture, the partners expect ADDvance O2 precision to give 3D Medlab precise, granular control over the oxygen concentration and humidity levels in the build chamber.

“Our experience with Linde shows that they are as committed to the same high standards of precision and excellence in Additive Manufacturing that we are,” added Gaël Volpi, CEO, 3D Medlab. “Full regulatory compliance is a fundamental cornerstone in our engineering and design process and our customers trust us to ensure all proper measures and controls are in place.”

Linde initially began working with 3D Medlab when it supplied the company with its ADDvance powder cabinet, designed to retain the quality of valuable, sensitive metal powders used in the Additive Manufacturing process by protecting them from exposure to ambient air and humidity.

While the current collaboration between Linde and 3D Medlab is focused on Ti6AI4V lattice structures, future efforts will include an investigation of the potential of nickel titanium (also known as nitinol) in view of its excellent shape memory and super elasticity, both of which make it an ideal candidate for next generation stents.