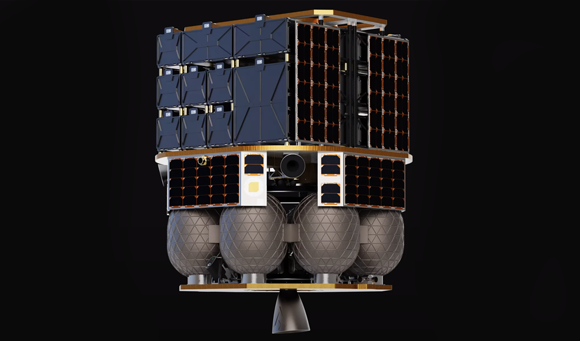

Launcher’s Orbiter with multiple metal AM components set for SpaceX rideshare

June 21, 2021

Space technology company Launcher, headquartered in Hawthorne, California, USA, reports that Orbiter, its universal orbital transfer vehicle and satellite platform – which features an additively manufactured propellant tank, combustion chamber, and injector as part of the chemical propulsion module – is contracted with SpaceX to fly via Falcon 9 to Sun-Synchronous Orbit (SSO) in October 2022.

Designed to be compatible with both Launcher Light and SpaceX Falcon 9 rideshare flights, Orbiter is interoperable with either launch vehicle via a common ESPA Grande adapter ring. It is capable of carrying up to 150 kg of customer satellite payload in a modular stack of CubeSat deployers.

The Orbiter can also be configured to accommodate small satellite payloads directly on an integration surface compatible with small satellite separation systems. It is equipped with Launcher’s signature combination of high-performance, low-cost, high-thrust chemical propulsion that allows customers to customise their payload orbit according to their mission needs.

Launcher states that Orbiter allows small satellite constellation developers to take advantage of the price point of the SpaceX rideshare programme to build their constellation at optimum cost and timing. To complete their constellation with additional orbits and schedules, customers can purchase a launch service using Orbiter for a dedicated ride to orbit on Launcher Light, Launcher’s own small orbital launch vehicle, slated for its first flight in 2024.

“Orbiter delivers the best of both worlds: the ability to maximise and tailor launch opportunities for your constellation using SpaceX’s rideshare program, as well as the option to design additional complimentary missions on a small, dedicated Launcher rocket when orbit requirements or schedules dictate,” commented Max Haot, Launcher founder and CEO. “Customers benefit from working with the same partner, mission team, contract, qualification and regulatory processes, satellite interface, and orbital transfer vehicle hardware and software platform.”