Laseradd showcases metal Additive Manufacturing systems at TCT Asia

March 2, 2018

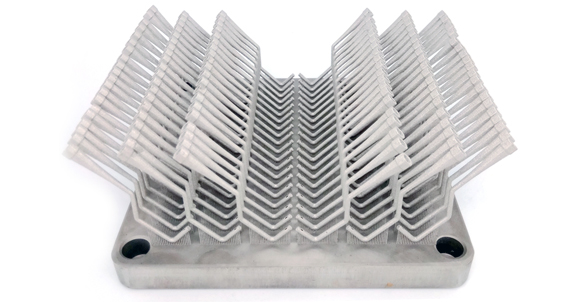

The DiMetal-280, the largest of Laseradd’s metal AM systems, offers a build area of 250 x 250 x 300 mm (Courtesy Laseradd Technology (Guangzhou) Co., Ltd)

Laseradd Technology (Guangzhou) Co., Ltd, Guangzhou, China, has showcased four of its metal Additive Manufacturing systems at TCT Asia, running from March 1-3 in Shanghai, China. The company specialises in Selective Laser Melting (SLM) system manufacture, sales and in providing metal Additive Manufacturing services to its customers.

On display at the show was the company’s DiMetal series of metal AM systems, said to be capable of processing a range of materials including titanium, high-temperature alloys, cobalt chromium alloy, stainless steel and aluminium alloys. The DiMetal range includes three systems – the DiMetal-50, DiMetal-100 and DiMetal-280.

Metal additively manufactured automotive spray hose component for VW (Courtesy Laseradd)

The DiMetal-50 offers the smallest build area at 50 x 50 x 50 mm, with the DiMetal-100 offering a maximum build area of 100 x 100 x 100 mm and the DiMetal-280, the largest of the systems, offering a build area of 250 x 250 x 300 mm for larger scale part production.

Founded by a team with a reported fifteen years’ experience in the development of powder bed fusion (PBF) metal Additive Manufacturing equipment and technology, Laseradd states that it is devoted to the development of a brand, technology, products, services and training to support local and national manufacturing and scientific research enterprises at all levels.