Laser Wire Additive Manufacturing used to build full-size rocket thrust chamber

April 28, 2020

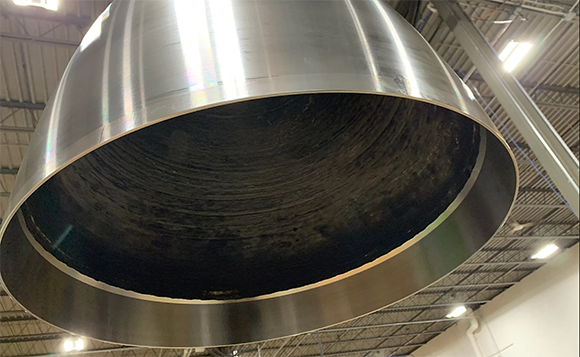

ADDere, the metal Additive Manufacturing division of Midwest Engineered Systems Inc., headquartered in Waukesha, Wisconsin, USA, has successfully used its Laser Wire Additive Manufacturing technology to build a full-size rocket thrust chamber assembly, which merges a combustion chamber and nozzle.

Measuring 1070 mm high and 610 mm diameter and additively manufactured in stainless steel, ADDere was reportedly able to build the assembly with metallurgical qualities approaching billet grades. The rocket nozzle assembly was said to have taken only twenty hours to build; after Additive Manufacturing, it was machined to its finished shape, having a 3 mm sidewall on the thrust chamber body with thicker walls in the combustion chamber portion.

“It’s so rare that we get to show some of the capabilities we have, especially one that has gone through finish machining,” stated Scott Woida, President ADDere. “I think it gives a new perspective to what is possible with the technology.”

“It’s the savvy engineer who’s got their fingers on the pulse of what’s next that truly understands the potential the ADDere systems can provide. This part is a glimpse into that future.” – Pete Gratschmayr, ADDere

Click to TweetThe rocket thrust chamber assembly demonstrates the advantages of Laser Wire AM for large-scale components, including the key ability to combine assemblies of parts into one component, allowing for far more advanced geometries than were previously available and eliminating the need to rely on large production quantities to drive prices down in manufacturing technologies where custom tooling is required.

“I think a lot of people only see the straight-from-the-printer parts we show but miss the potential of the process that’s unveiled after finish machining,” explained Pete Gratschmayr, VP of Sales, ADDere. “It’s the savvy engineer who’s got their fingers on the pulse of what’s next that truly understands the potential the ADDere systems can provide. This part is a glimpse into that future.”