Kurtz Ersa enters into metal AM market with launch of Alpha 140

April 19, 2021

Kurtz Ersa, a producer of components, systems and equipment for the optimisation of manufacturing processes, headquartered in Kreuz-wertheim, Germany, has entered the Additive Manufacturing equipment market with the release of its Alpha 140 Laser Beam Powder Bed Fusion (PBF-LB) metal AM machine.

Said to combine innovative Additive Manufacturing technology with simple operation and lower system costs, the Alpha 140 is aimed at small and medium-size companies, particularly those in the moulding and tooling industries where the Alpha 140 is ideal for complex geometric structures such as moulds with internal, near-contour cooling. The company believes the Alpha 140 particularly shines with small batch sizes, allowing users to save on tooling, something which may also prove attractive to universities and research institutes.

During the machine’s development, engineers worked to meet the desire for a simple, economical, and open architecture, as well as allowing the user to process special materials, produce customisable designs and provide geometric freedom. With these specifications, and the comparatively low costs in mind, Kurtz Ersa states that the Alpha 140 is an ideal entry point into metal Additive Manufacturing.

Optimised production process

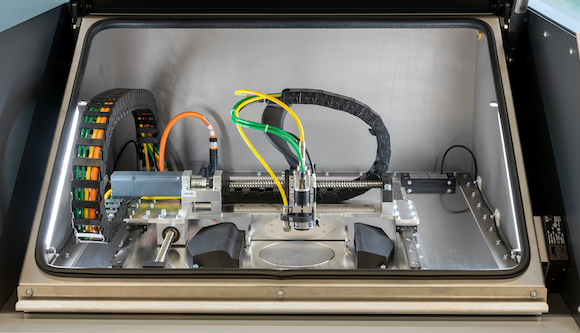

The Alpha 140 utilises a 140 W fibre-coupled diode laser, enabling the production of fine details and thin wall depths, while the laser’s gantry mounting enables a constant focus diameter throughout the entire installation space. Layer thicknesses between 30 µm and 90 µm allow for a component- and material-dependent optimised manufacturing process. The spindle-driven axis system allows high positioning and repeatability of the laser system, while a laminar-shielding gas flow creates optimised processing conditions for both protecting the laser optics and for the inert welding process.

The round build envelope of the machine measures 140 mm in diameter with a maximum build height of 200 mm. With a footprint of just 170 x 95 cm, and an optional integrated nitrogen generator enabling self sufficiency without an external gas supply, the ‘plug and produce’ machine is ideal for space-saving use in production environments and research labs alike, where connection by means of a cold appliance plug and optional air cooling enables simple installation.

The components manufactured on the Alpha 140 are said to reach strengths comparable to traditional PBF-LB machines with densities greater than 99.5%. Being up to 80% more economical, Kurtz Ersa states the Alpha 140 can offer a worthy industry contribution to the European Green Deal’s goal of climate neutrality by 2050.

Available materials and parameter sets for the Alpha 140 include stainless steels (such as 1.4404), nickel-base superalloys (IN625 and IN718), tool steel and aluminium alloys (AlSi7Mg), with more materials upon request. The open system design also enables in-house material qualifications and the development of new types of materials. Because the Alpha 140 is designed as a complete AM system, it also has its own software for data preparation (either via preset parameters or extensive manual input), from component design to simulation and generation of support structures to data preparation, allowing the mapping of the entire AM workflow.

Cooperation with LMI

The Alpha 140 was developed by Laser Melting Innovations GmbH & Co. KG (LMI), a spin-off from the RWTH Aachen University, where Additive Manufacturing has been an essential part of development activities for over twenty years. The cooperation with Kurtz Ersa, with its access to a worldwide sales and service network, enabled the machine’s rapid market launch.

“In Aachen, the cradle of metal Additive Manufacturing, more than 200 top developers, specialists and young talents are continuously working on the topic of Additive Manufacturing,” commented Professor Johannes Henrich Schleifenbaum, one of LMI’s founders. “In addition to processes and machines, we have a particular focus on the benefits for industrial users, from component design through 3D printing and post-processing to the ready-to-use component. Here, we have direct access to a wealth of experience of more than 1,000 man-years. We make this available to our partners.”

From left to right: with LMI is founder Dawid Ziebura, Sven Scheres, Steffen Stahlhacke, founder Prof Dr-Ing Johannes Henrich Schleifenbaum; with Kurtz Ersa is: CEO Rainer Kurtz, Head of Technology Victor Romanov, and Managing Director Uwe Rothaug (Courtesy Kurtz Ersa)

After signing a cooperation agreement in August 2020, the assembly of the initial AM machine began just ten weeks later, with the first delivery taking place in December 2020. Further machines have been installed and are already in production – such as those at the German Aerospace Centre (DLR) and the Fraunhofer IWKS (Research Institution for Materials Recycling and Resource Strategies). Orders for other Alpha 140’s have been confirmed, including one for the Technical University of Cologne, or are close to completion directly with industrial companies.

“3D metal printing complements our relationships in the manufacturing scene and fits perfectly with our strategy ‘Global. Ahead. Sustainable.’, with which we present ourselves as technology leaders in our respective markets,” added Rainer Kurtz, CEO of Kurtz Ersa. Together with Managing Director Uwe Rothaug, Kurtz was also pleased with the “fantastically short time to market” of the Alpha 140.

The cooperation between the companies is a classic win-win scenario. For Kurtz Ersa, the process knowledge of the LMI team in the field of Additive Manufacturing was the key to entering this new business field. For its part, LMI, as a young company, was able to utilise the sales and service channels of the more established Kurtz Ersa as a perfect complement to the roll-out of its metal AM technology.

The Alpha 140 is manufactured at the Kurtz Ersa production site in Kreuzwertheim. A 24-hour service is offered thanks to a global presence, with live presentations being available in the the Kurtz Ersa Corporation’s demo centres. An Alpha 140 specific showroom is also planned for LMI in Aachen.