Kugler to showcase anti-friction hybrid AM parts at Formnext 2021

November 15, 2021

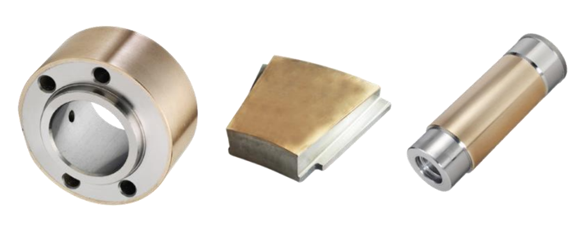

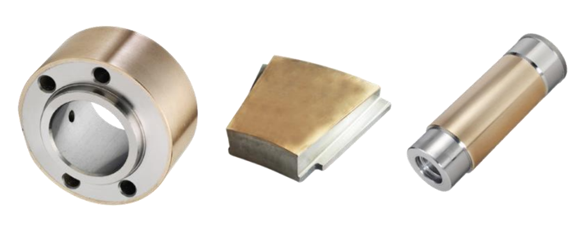

Kugler Bimetal, headquartered in Geneva, Switzerland, is set to exhibit a wide variety of large, anti-friction bimetallic parts at Formnext 2021. The parts are produced by combining Additive Manufacturing technologies, such as laser-based Directed Energy Deposition (DED), with traditional manufacturing technologies including machining and casting.

Bimetallic parts combine the properties of different materials (such as steel and proprietary bronze alloys) to combine high anti-friction performance with strong mechanical resistance. Kugler utilises these hybrid technologies in an effort to provide customers with the best value and high wear resistance, durability, lifespan and ease of maintenance – requirements which are critical for sectors such as offshore wind, as well as in components such as high-performance hydraulic pumps, and gearboxes.

Kugler Bimetal has been operating since 1854 and has developed a unique expertise in high-end, antifriction solutions. Throughout its history, the company has tailor-made solutions using different alloys in order to fulfil customer requirements.