Koszalin University adds ExOne’s Innovent+ metal Binder Jetting machine

September 14, 2020

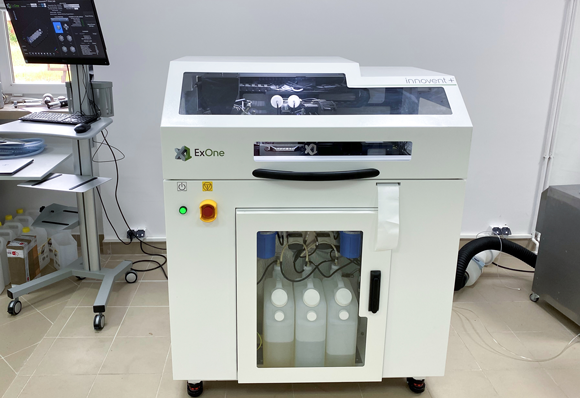

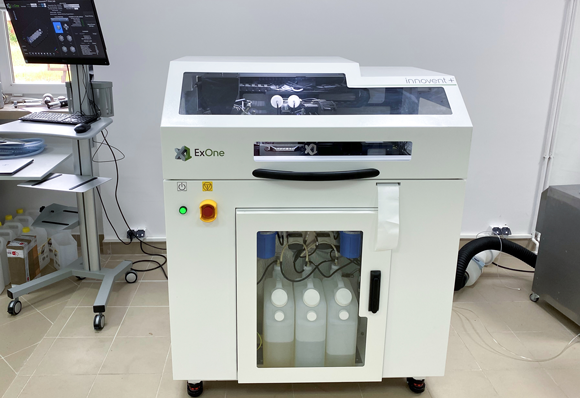

The ExOne Company, North Huntingdon, Pennsylvania, USA, reports that the Koszalin University of Technology, Koszalin, Poland, has invested in one of its metal Binder Jetting Additive Manufacturing machines. The new Innovent+ from ExOne will allow students to research and discover the potential of Additive Manufacturing, and will also be used to support local companies in highlighting the advantages of AM.

The Innovent+ uses ExOne’s patented Binder Jetting technology, an additive procedure which uses a liquid binding agent that is selectively applied to powder particles. Following the building process, excess material is removed and the object is sintered in a high temperature furnace.

“I have been following the development of the Binder Jetting technology for several years now, and based on its potential and the diverse application areas, I decided to invest in such a machine for our new research centre,” stated Prof Błażej Bałasz, professor at the Faculty of Mechanical Engineering.

Students at the Faculty for Mechanical Engineering are said to be researching innovative methods for manufacturing machine parts. To further expand this area of research, the faculty implemented the ‘Rapid Prototyping Center’ project, so the research centre is equipped with high-tech devices to research Additive Manufacturing technologies.

In addition to other devices, the centre has a laser scanner and a unique device for manufacturing metal powders under laboratory conditions, as well as an inspection machine for testing the strength and wear-resistance of the parts.

The faculty is currently using the Innovent+ metal AM machine to research 316L metal powder and plans to use other alloys, such as 17-4PH, copper and tool steel in the future. It also plans to enter into various collaborations with local companies, with other practical research projects planned within this scope.