Kolibri powder drying system to minimise cracking in AM parts

September 2, 2020

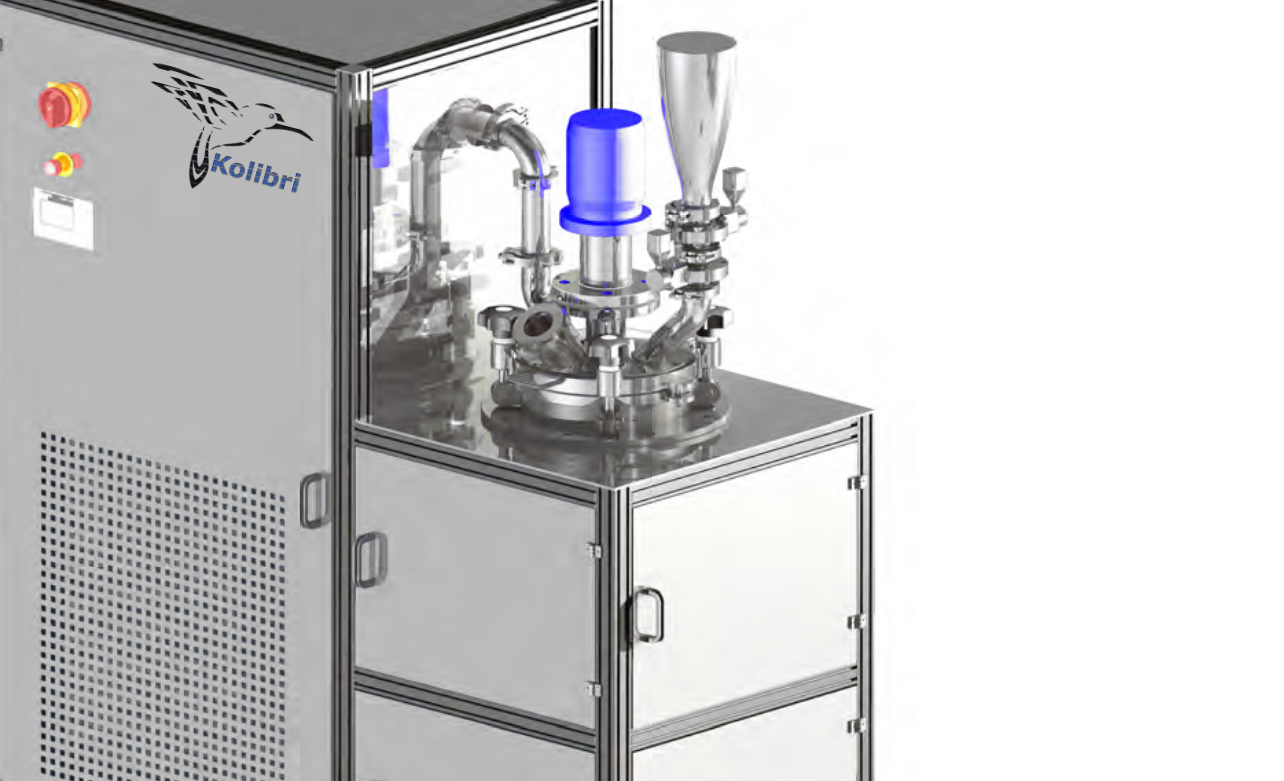

Kolibri Metals GmbH, Amtzell, Germany, has launched the ATACAMA powder drying system, a machine which dries metal powder to a moisture content of less than 4% to increase the buildability of tool steels with carbon contents, such as H11 and H13.

Moisture is a significant factor in the formation of cracks in these materials when processed by Laser Beam Powder Bed Fusion (PBF-LB), as well as the formation of ‘zebra-patterns’ in materials, annealing colours, poor component surfaces, inhomogeneities in structure, poor flowability and ultimately a fluctuating service life and component quality.

Kolibri is reported to be highly experienced in the Additive Manufacturing of high-carbon tool steels and metal matrix composites by PBF-LB. For these materials, extremely low levels of moisture are essential. However, in its series production of extremely high-strength components out of tool steel, in conjunction with carbides or diamond powder, Kolibri found that there was no solution on the market which would enable it to achieve the level of powder dryness and process stability required for these applications.

In response to this need, the company developed the ATACAMA system, said to dry metal powders in a standardised and simple manner. The machine is expected to enable users to correct the fluctuating quality of powder shipped from powder manufacturers, significantly improves powder flowability, and can be used for all inorganic powder materials.

Three models will be made available in September 2020 when the ATACAMA goes on sale:

- ATACAMA 10, with a drying speed of 10 kg every few hours

- ATACAMA 10 K, able to dry 10 kg of powder in under an hour

- ATACAMA 10 KA / 10 A, which offers the additional option to preserve dried powders in an argon atmosphere