Junchen 3D partners with HBD to expand range of AM services

September 24, 2021

China’s Junchen 3D Printing Technology (Shanghai) Co., Ltd., is an established Additive Manufacturing services provider offering both polymer and metal AM production along with industrial design, post-processing and CNC capabilities. The company was successfully listed on the Shanghai Stock Exchange in December 2020 and now has over 200 AM machines installed across its six facilities, of which over 150 are classed as industrial grade systems.

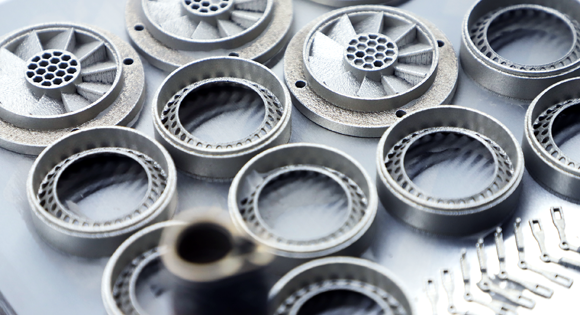

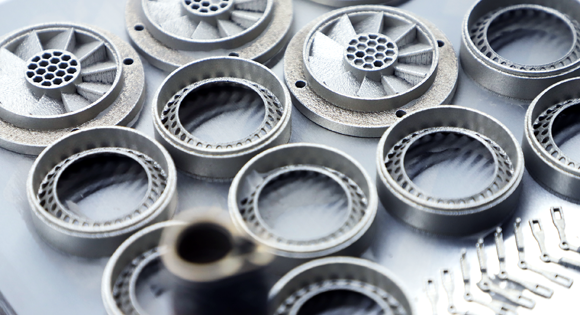

The list of equipment at Junchen 3D includes three HBD-280 metal Laser Beam Powder Bed Fusion (PBF-LB) AM machines from Guangdong Hanbang 3D Tech Co., Ltd, (HBD), with plans to purchase further HBD machines to meet the growing demand for metal AM production. With a build size of 250 × 250 × 300 mm, the HBD-280 is designed for a wide range of applications and can be supplied with single or dual laser configurations.

The AM machines from HBD have expanded the range of metals that Junchen 3D can now handle. The HBD-280 is capable of processing stainless steel, cobalt-chromium alloy, tool steel, titanium alloy, high-temperature alloy, aluminum alloy, Hastelloy and refractory metals such as tungsten and tantalum. In addition to tooling, medical equipment, and automotive parts manufacturing, the company is now also targeting mass customisation as well as high value personalised products.

Including both polymer and metal production, the company has, to date, additively manufactured some 13 million parts across numerous sectors, including for medical, aerospace, automotive and domestic applications. As well as clients within China, Junchen 3D has exported parts to customers in over forty countries.