Jesse Garant Metrology Center launches high-energy CT inspection service for AM parts

January 18, 2018

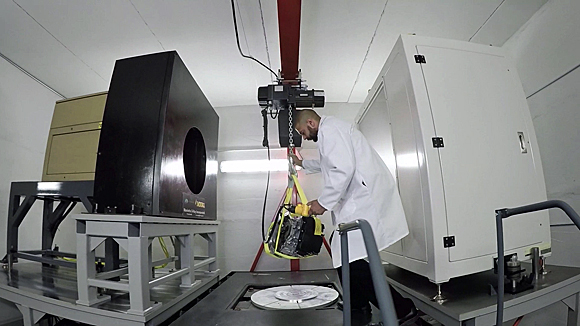

The system pairs a 3 MeV cone-beam X-ray source with a large format 2k x 2k flat panel digital detector (Courtesy Jesse Garant Metrology Center)

Jesse Garant Metrology Center, Dearborn, Michigan, USA, has launched a new high-energy industrial computed tomography system. The company will reportedly be the only private lab in the world to provide this specialised inspection service, which it says could transform the landscape for non-destructive testing (NDT) and support for Additive Manufacturing.

The system pairs a 3 MeV cone-beam X-ray source with a large format 2k x 2k flat panel digital detector. It will reportedly be able to accommodate rapid inspection of mid-size parts, up to 113 cm in diameter by 160 cm in height. While existing high-energy CT services may take between four and sixteen hours to complete scans, the new system is reported to be able to scan parts in less than an hour.

The system’s capabilities are expected to directly support Additive Manufacturing, allowing for feasible internal inspection and validation of both metal and plastic additively manufactured parts. This includes the identification of defects like porosity, residual powders, first article inspection, wall thickness variations and actual to nominal comparisons for determining out of tolerance features.

Jesse Garant, President of the Jesse Garant Metrology Center, stated, “We’re helping manufacturers qualify and validate printed parts that either weren’t possible because of limitations with existing technologies or weren’t feasible because the service was too costly or took too much time. We aim to support innovation by providing internal inspection of parts that would otherwise go into production without proper inspection.”

In addition to the reported reduction in inspection time for parts and assemblies, the service will also enable the inspection of complex assemblies, with the potential to allow for cleaner separation of internal components and inspection of higher density materials not possible with lower energy systems.

This new technology is the result of three years of planning, design, development and construction by the centre, amassing a total $4.5 million investment. The new system is said to have required sourcing from both local and international manufacturers, vendors and specialists, including the construction of what is thought to be the largest 1 m x 1 m flat panel detector in the world.