IRT Jules Verne selects AlphaStar’s Genoa 3DP for Additive Manufacturing simulation

January 24, 2019

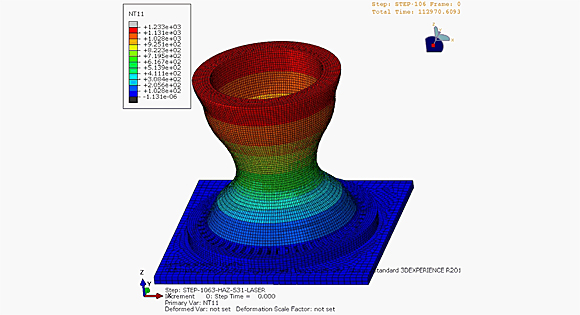

Using multi-scale progressive failure analysis methods to replicate the entire AM process, Genoa 3DP is reported to be able to determine voids, cracks and other manufacturing anomalies (Courtesy AlphaStar)

IRT Jules Verne, a mutualised industrial research institute based in Bouguenais, France, has selected AlphaSTAR’s Additive Manufacturing simulation product, Genoa 3DP, to model and simulate AM processes as well as to minimise trial & error, scrap rate, and the overall cost of AM. Created in 2012 as part of France’s Investissement d’avenir (Investing for the Future) programme, the Jules Verne Technology Research Institute is dedicated to advanced manufacturing technologies.

IRT Jules Verne required a robust and accurate simulation tool to provide a deeper understanding of material modelling & characterisation and part performance simulation related to the Additive Manufacturing processes, while also aiming to save costs and improve productivity. After evaluating different solution providers, the engineers at IRT Jules Verne identified Genoa 3DP.

“We needed software capable of analysing the materials, modelling the AM process and accurately replicating composite SLS & FFF printing methods,” stated Tuan Linh Nguyen, R&D Simulation Engineer at IRT. “With advanced features, such as analysis of temperature-dependent material properties beyond glass transition temperature and the high compatibility with our numerical tools, we felt Genoa 3DP was the perfect fit.”

“We are delighted to collaborate with IRT Jules Verne and their reputable partners,” commented Dr Rashid Miraj, AlphaStar’s Director of Technical Operations. “AlphaStar brings nearly 30 years of experience of providing test validated simulation technology so end-users are able to produce reliable analysis to predict the behaviour of advanced materials under various manufacturing processes such as Additive Manufacturing. We look forward to having our solution play a role at IRT.”

Genoa 3DP simulates the Additive Manufacturing process to accurately predict the deflection, residual stress, damage initiation and crack growth formation associated with as-built AM parts. Advanced Multi-Scale Progressive Failure Analysis methods are used to replicate the entire AM process from the level of material characterisation to process simulation to in-service qualification.