IperionX and Carver Pump to produce titanium parts for US Navy

February 7, 2023

IperionX Ltd., Charlotte, North Carolina, USA, has partnered with Carver Pump, Muscatine, Iowa, to offer additively manufactured titanium pump components to the US Navy. Carver will design these components, guide IperionX on prototyping, and lead the qualification process.

The US Navy’s Naval Sea Systems Command (NAVSEA) has developed Additive Manufacturing processes for over 500 approved parts used in US ships and submarines. The Governor of Virginia and the US Navy are accelerating efforts to scale AM, having recently opened the ‘Additive Manufacturing Center of Excellence’ in Danville, VA, located twenty-five miles from the site of IperionX’s new Titanium Demonstration Facility.

“In just four months, we’ve seen dynamic progress from IperionX,” stated Glenn Youngkin, Governor of Virginia. “As they continue to develop synergies with Carver Pump and the US Navy using 100% recycled titanium scrap as feedstock which will soon be produced in Halifax County, we look forward to seeing IperionX’s continued growth and success.”

High-performance pumps require high-performance materials

The US Navy selects titanium centrifugal pumps for their exceptional corrosion resistance, performance, and longevity in demanding naval applications. These pumps are critical for fire suppression, seawater cooling, radar and electronics cooling, main propulsion seawater, bilge, and desalination.

Carver has been providing high-performance centrifugal pumps to the US Navy since World War II. Carver pumps are installed on all current Navy ship building programs, including Ford Carriers, Zumwalt Destroyers, Aegis Destroyers, Littoral Combat Ships, America Big Deck Amphibious Assault Ships, San Antonio Amphibious Transport Docks, and Virginia Submarines.

“We are delighted to be working with IperionX to help introduce domestic sourced, 100% recycled titanium into the US Navy’s supply chain. When coupled with benefits of Additive Manufacturing, the partnership provides a significant potential to benefit to Navy operations through the rapid production of complex, operation critical titanium parts, providing a potential reduction in lead times and increasing equipment availability,” added Andrew Carver, Carver CEO. “We see this partnership as the first step in a larger relationship focused on both Navy surface ships as well as new parts for other marine applications.”

High-performance titanium pump components are mostly produced via titanium casting, a very high-cost manufacturing method which can present significant problems due to two key factors: titanium’s high melting point (1,670ºC) and high reactivity with oxygen. Therefore, to avoid unwanted reactivity, the specialised vacuum melting of titanium and then pouring into specially designed ceramic moulds is required.

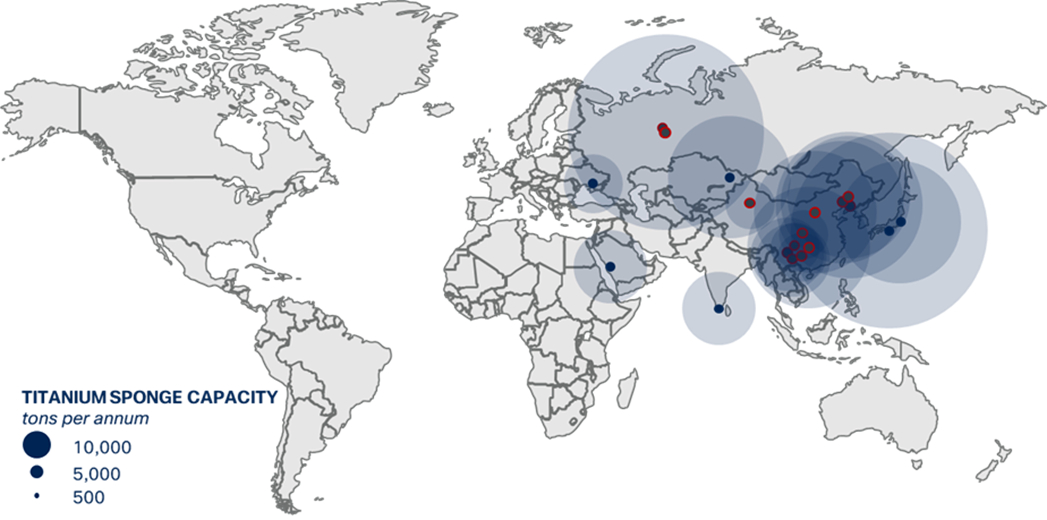

The US, however, currently has no domestic capacity to manufacture the large titanium castings required for high-performance centrifugal pumps, and this has led to long lead times for new pump components sourced from a foreign controlled supply chain. IperionX’s cheaper, lower-carbon, US-based titanium powders can be used to additively manufacture these specialised titanium pump components. This is expected to provide the US Navy with the capability to significantly reduce lead times for critical parts, increase equipment availability, and sustainably re-shore a critical US titanium metal supply chain.

IperionX is currently producing high-quality titanium metal powders from 100% recycled titanium feedstocks for customer qualification at its titanium production pilot facility in Utah. This titanium production facility has reportedly achieved processing yields approaching 100% from low-grade scrap without the need for blending with high-grade primary titanium metal.

Re-shoring US titanium

IperionX has successfully engaged with the US Navy to detail the company’s plans to sustainably re-shore the US titanium supply chain, that aims to reduce critical titanium component lead times, lower costs, and reduce carbon emissions.

These discussions involved senior leadership in NAVSEA, including the Office of the Chief Engineer for Ship Design, Integration and Naval Engineering, the Shipbuilding Industrial Base Task Force and Program Executive Office – Strategic Submarines. IperionX has also been in discussions with the US Defense Logistics Agency Strategic Materials agency on the potential for recycling titanium scrap inventory for use across the Defense Industrial Base.

In addition, IperionX is collaborating with Naval Air Systems Command to produce flight critical additively manufactured titanium components for Navy aircraft. These discussions build upon IperionX successfully winning the US Air Force Research Laboratory’s titanium recycling Grand Challenge and highlights the importance of sustainably re-shoring a US titanium supply chain for domestic and allied defence industries.

NAVSEA has publicly stated targets to develop technical standards for additive manufactured components to increase operational readiness. These aim to manufacture obsolete and long-lead time components, and also enhance defence capabilities by manufacturing unique component designs not otherwise possible. Importantly, the current lead time for large, specialised titanium castings is approximately one to two years, compared to one to three months when manufactured with titanium powders via Additive Manufacturing.

“Our partnership with Carver is another important milestone for the rapid commercialisation of IperionX’s breakthrough titanium technologies,” stated Anastasios (Taso) Arima, IperionX CEO. “These patented technologies can efficiently recycle domestic titanium scrap metal at lower cost than existing processes, and this high-quality titanium metal can be used for a range of manufacturing technologies, including Additive Manufacturing. We look forward to working closely with Carver to rapidly prototype and deploy titanium components for a wide range of centrifugal pump applications in US Navy platforms.”

Download Metal AM magazine