Intech, IRES, and Conify partner to shorten PBF-LB alloy development time

December 1, 2021

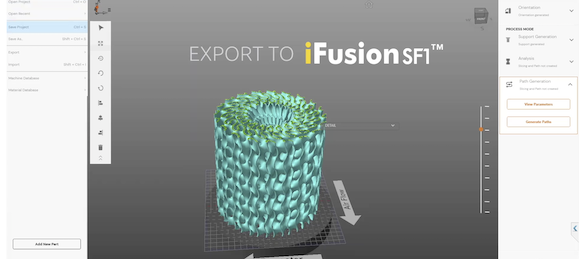

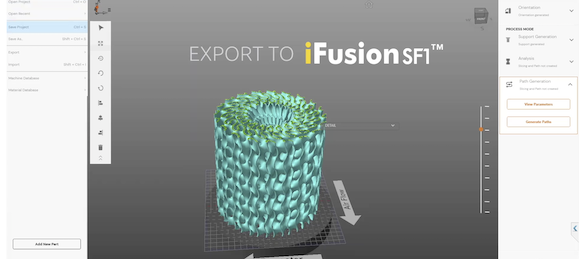

Over the past year, Intech Additive Solutions Pvt Ltd., Bangalore, India, has been collaborating with Greek-based Conify and IRES to explore the possibility of shortened alloy development time using its Laser Beam Powder Bed Fusion (PBF-LB) iFusion SF1 machine and AMOptoMet parameter optimisation software. The companies exhibited together at Formnext 2021.

“By identifying powder characteristics playing a decisive role to the final part quality through our unique material digitisation process, Conify enables the development of individual material-process parameters pairs for high-density, defect-free additively manufactured parts,” stated Dr Evangelia Caraxis, Managing Director, Conify. “However, the major challenge lies in establishing and qualifying the print process parameters, as it is an iterative process that can take several weeks to months. Intech’s AMOptoMet, in turn, gives users a reliable tool to successfully calculate print parameters and predict print properties with a simulated iterative approach. This reduces the development time to hours/days.”

The purchase of the iFusion SF1, Intech’s PBF-LB metal AM machine, complements the vision of transforming innovative ideas into products. With build dimensions of 150 mm x 180 mm and a powerful 500 W Laser, the iFusion SF1 is primarily geared towards towards faster material verification for PBF-LB, alloy parameter developing and the prototyping of small to mid-size components. It comes with AMBuilder, Intech’s pre-build design software, and the option to add AMOptoMet.

AMOptoMet is said to reduce cycle times for design experimentation by up to 70% by use of multiple modules, including: surface roughness, image analysis, material definition, max power and variable gradient. The software can be used as part of any PBF-LB machine.

“We are pleased that IRES and Conify, an organisation leading the way in powder qualification and establishing AM process flow, have found its ideal partner in Intech in the implementation of AM technology,” stated Pradeep Nair, vice president of Sales at Intech. “The cost-effective iFusion SF1 is an ideal solution for Conify as the powerful 500 W Laser will allow them to experiment with a wide range of exotic alloys. The system can also print with as low as 7-10 kg of powder, which is ideal for a research environment, especially when combined with AMOptoMet.”

He concluded, “We are confident that this partnership will not only immensely benefit all alliance organisations, but also the AM industry at large from the new materials that will be qualified for [PBF-LB].”