InShaPe project aims to increase competitiveness of metal Laser Beam Powder Bed Fusion process

July 18, 2022

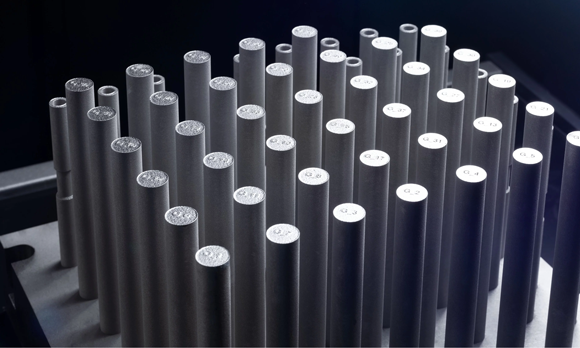

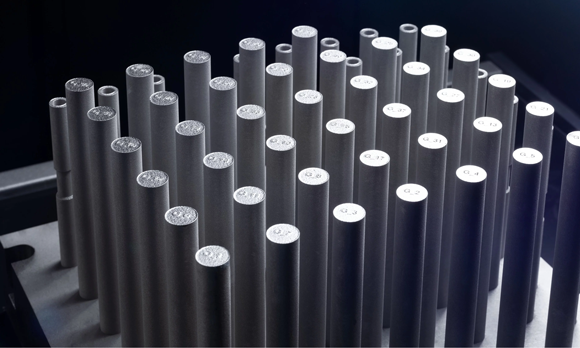

A new research and innovation project called InShaPe, conducted by the Technical University of Munich (TUM) and nine other partners from seven countries, has been launched to further develop metal Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing. The project has received €6.8 million in funding from the EU and is managed by Prof Dr-Ing Katrin Wudy, Head of the Professorship of Laser-based Additive Manufacturing at TUM.

The project will particularly focus on the flexible adaptation of the laser spot during the PBF-LB process to enable efficient and cost-effective production. The improved manufacturing process is based on a high-performance optical module with programmable intensity distribution and AI techniques to determine the optimal beam shape for the target object, determined for example by the material type and geometry.

InShaPe also aims to develop an innovative process monitoring and control system for quality analysis that integrates multispectral imaging, i.e. simultaneous observation of light of different wavelengths in the area of Additive Manufacturing.

“The combination of these two new technologies enables efficient and advanced exposure strategies so that even the most demanding production of complex special components works right away,” commented Prof Dr-Ing Wudy.

The project partners have set the goal of further developing this form of Additive Manufacturing into a commercially wide-ranging manufacturing technology in order to outperform conventional manufacturing processes, such as die casting, in terms of precision and sustainability in the future.

This is due to the fact that the adaptation of the laser beam shape and the new exposure options enable an energy- and material-efficient production process. At the same time, the InShaPe innovation aims to demonstrate the competitiveness of Additive Manufacturing compared to traditional manufacturing processes in terms of unit costs, flexibility and production volume. The AI-supported control and operation should also enable non-highly qualified workers to use the new process.

The main goal of the InShaPe project is to further develop and demonstrate an innovative metal PBF-LB process for four industrial applications in the aerospace, energy and automotive industries. The project hopes to achieve the following advantages: a seven times higher production rate, over 50% lower costs, 60% less energy consumption, and 30% less waste.

The InShaPe project will run until the end of May 2025, and in the long term, the successful development and marketing of InShaPe technologies is intended to strengthen the European metal PBF-LB manufacturing industry as a leading provider of highly complex parts and set new best-in-class standards for digital, resource-efficient and agile laser-based production methods.