Impact Innovations develops cold spray AM process for Ti6Al4V

December 14, 2020

Impact Innovations GmbH, Rattenkirchen, Germany, a leading technology provider for industrial cold spray systems and processes, has developed a cold spray Additive Manufacturing process for Ti6Al4V using nitrogen as the propellant.

Cold spray Additive Manufacturing is particularly useful for the production of large parts, which can pose problems for today‘s Powder Bed Fusion (PBF) AM processes due to equipment size limitations or protective atmosphere necessity, especially when depositing reactive materials such as Ti64.

Ti6Al4V is typically used in marine and defence applications, the manufacturing of aerospace structural parts, gas turbine components and biomedical implants and prostheses.

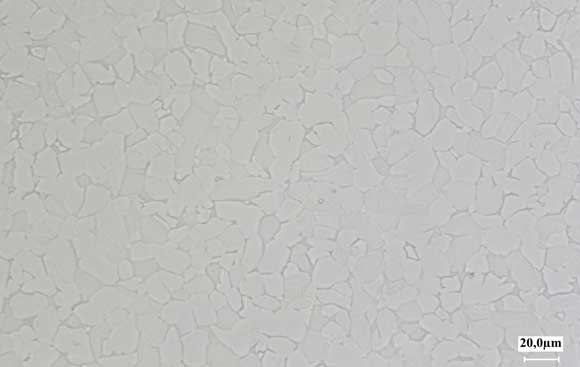

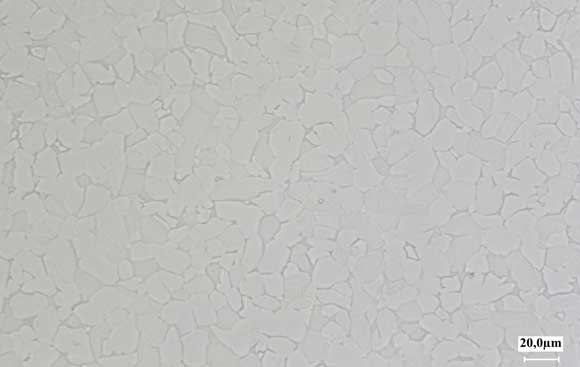

Until now, Ti6Al4V was considered one of the most challenging materials for cold spray deposition due to the high critical velocities the material must withstand during the deposition process, which resulted in porosities in the cold spray deposits of 3% and higher.

Impact Innovations states that its combination of cold spray hardware, process parameters and post-treatment procedure has resulted in porosity levels of < 0.2% and final mechanical properties exceeding the requirements set by the ASTM F3001, ISO 5832-3 and AMS 4930 standards.

In contrast to other Additive Manufacturing technologies, powder particles are not melted during the cold spray process; the bonding occurs due to plastic deformation. Unlike other common AM processes, such as Laser Beam Powder Bed Fusion (PBF-LB), Electron Beam Powder Bed Fusion (PBF-EB) or Wire-Arc Additive Manufacturing (WAAM), cold spraying does not require high temperatures. Thus, it is possible to deposit components without the use of any protective atmosphere, with almost no dimensional limitation, and in the absence of thermal residual stresses. The material efficiency from powder to deposit is more than 97%.