Hyde Aero Products expands into metal Additive Manufacturing

May 20, 2021

Part of the Hyde Group of companies, aerospace design and manufacturing solutions provider Hyde Aero Products (HAP), Dukinfield, UK, has established a new Additive Manufacturing subsidiary, Hyde Additive Technologies. Recognising that AM will play an increasingly important role in future aerospace components, the company has begun investing in the technology to promote cost-saving solutions.

Components developed so far include checking fixtures for small detailed parts and masking aids for HAP’s treatments facility. The company has also used this rapid prototyping technology to produce, to scale, complex parts at RFQ stage, thus gaining a better understanding of machining strategies. While, to date this work has been with polymers, HAP now wishes to move into metal AM.

Supported by customer Leonardo Helicopters, two Class III helicopter parts were identified as test cases for metal AM as part of a weight-reduction initiative: forward and aft service handles. HAP hoped to answer whether metal AM presents a viable, cost-effective solution and, if so, how does the company develop a business case for the adoption of metal AM in the future?

Following a meeting with the company, a process development support package was agreed to be delivered jointly by the National Centre for Additive Manufacturing (NCAM) and Renishaw engineers. A process design and topology optimisation study was first undertaken, beginning with a baseline stress analysis for a current machined-from-solid AlSi10Mg aluminium alloy handle. This was used to evaluate different AM handle designs featuring a variety of internal lattice structures, as well as a hollow handle, indicating weight savings between 20% and 45% were possible.

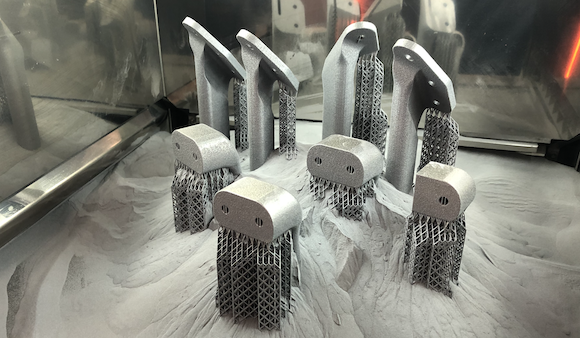

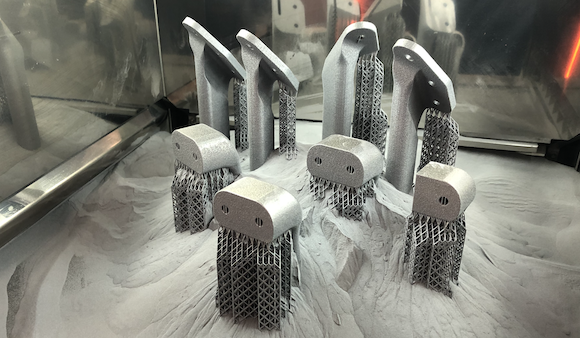

Renishaw conducted a first build on a Laser Beam Powder Bed Fusion (PBF-LB) AM500Q machine comprising a selection of vertically manufactured Forward and Aft Service Handles with the aforementioned hollow and latticed internals. In order to obtain an indication of the likely manufacturing cost, this was followed by a second build containing sixteen forward service handles with hollow internals.

The only critical dimension on the handle is the distance between mounting hole centres and, after CMM measurement of this across the parts, it was concluded that building in the vertical orientation would not provide sufficient accuracy in production. For the next two builds, the Forward Service Handles were additively manufactured horizontally in fours, this being the optimum orientation for maintaining mounting hole positional accuracy; in this configuration some internal support is necessary. The first build used a conventional internal structural lattice, and the second, a light-weight lattice giving support only.

In the final DRAMA Business Case support package, NCAM engineers worked with HAP to develop a business case model for these handles, which could also be used for other metal AM parts in support of the company’s planned expansion.

Paul Mellor, Technical Director, stated, “The DRAMA programme came along at the perfect time for Hyde, as we develop our AM capabilities in metal. The work on the helicopter door handles gave us a great insight into the AM design for manufacture process, and will inform our future discussions with Leonardo.”