Hospital reconstructs patient’s chest using titanium Additive Manufacturing

February 21, 2018

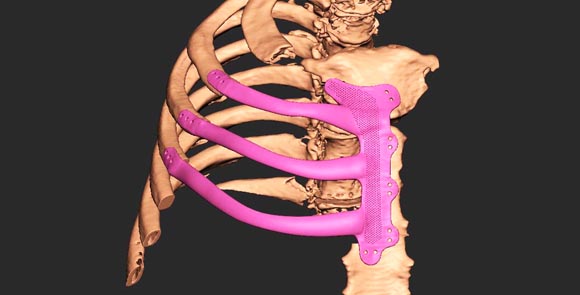

Using metal AM, the surgical team was able to produce a titanium implant to the patient’s exact fit and specifications (Courtesy NHS Wales)

Surgeons at Morriston Hospital, Wales, UK, have successfully rebuilt part of a patient’s chest using metal Additive Manufacturing. The titanium implant was additively manufactured on a Renishaw system, as part of a collaborative innovation project between the company and the hospital.

According to NHS Wales, the 71-year-old patient required the implant following surgery to remove an extensive sarcoma – a cancer growth in the soft tissue – from his chest, resulting in the removal of part of the breastbone and three ribs altogether. Though necessary, the surgery left the patient at risk of chest wall destabilisation and potential collapse.

Traditionally, the chest would have been reconstructed using a cement prosthesis. However, although hard-wearing, cement prosthetics do not provide an exact fit and can move within the body, causing issues such as dislocation, explained Ira Goldsmith, Cardiothoracic Surgeon at Morriston. In addition, cement prosthetics take around an hour and a half to prepare during surgery, putting the patient at increased risk of complications on the operating table.

To achieve a custom fit, the implant was designed by hospital staff based on CT scans of the patient’s chest (Courtesy NHS Wales)

Using metal AM, the surgical team was able to produce a titanium implant to the patient’s exact fit and specifications, as well as reducing the overall surgery time by around two hours. To achieve a custom fit, the implant was designed by Heather Goodrum, Morriston’s Biomedical 3D Technician, and Peter Llewelyn Evans, Morriston’s Laboratory Services Manager, based on CT scans of the patient’s chest.

During a reconstructive surgery taking approximately eight hours, the finished titanium implant was sewn into place and covered with a section of latissimus dorsi muscle harvested from the patient’s upper back. Following the procedure, Goldsmith stated, “We are very pleased with the outcome. The implant is a perfect fit. Titanium is very strong and any problems like dislocation are reduced or even eliminated because the implant is anchored securely to the ribs and breastbone.”

A post-surgical X-ray shows the patient’s reconstructed ribcage (Courtesy NHS Wales)

According to Morriston Hospital, this is the first time an implant of this kind has been produced using metal Additive Manufacturing in the UK. The hospital stated that Goldsmith will give a presentation on the implant’s development at the next meeting of the British Sarcoma Group, as well as the Society for Cardiothoracic Surgery in Great Britain and Ireland.