HiETA Technologies employs Simufact Additive for metal AM process simulation

July 4, 2018

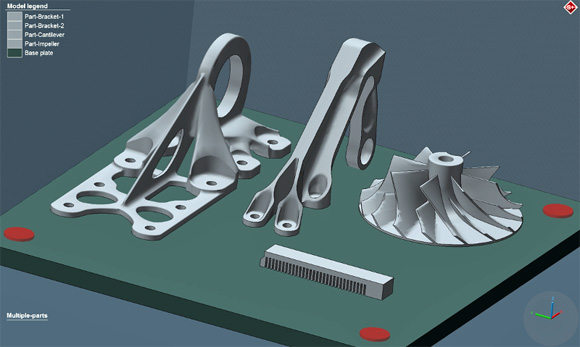

Simufact Additive offers scalable process simulation for the optimisation of Laser Powder Bed Fusion (LPBF) AM processes (Courtesy Simufact Additive)

Simufact Engineering, an MSC software company, has reported that HiETA Technologies Ltd, Bristol, UK, has chosen Simufact Additive to simulate the Additive Manufacturing process for predicting the deformation of parts for automotive, motorsport, aerospace, defense and energy industries.

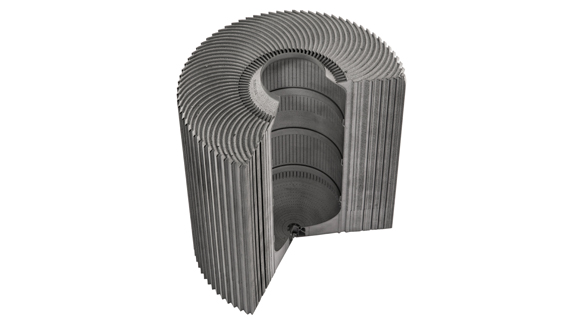

HiETA Technologies is a product design, development and production company specialising in thermal management and light weighting solutions, and offers services across the product life cycle from conception through design, analysis, manufacture, post-processing, quality assurance and testing.

The company uses metal Additive Manufacturing to build products and systems which it would not be possible to produce using conventional manufacturing methods. Five Renishaw AM systems are currently installed at its Bristol facility – four AM250 and one RenAM500M.

“Simufact brings value to our designs and products by providing unique insight and helping to reduce the number of design iterations, thus increasing efficiency. Its ease of use along with excellent customer service was a major reason to purchase,” stated Keith Parker, Senior Design Engineer of HiETA Technologies.

Additively manufactured heat exchanger by HiETA Technologies (Courtesy HiETA Technologies Ltd)

Simufact Additive is a scalable process simulation environment which enables Laser Powder Bed Fusion (LPBF) process optimisation with the aim of achieving ‘first time right’ part production. Its features include simulation of all the key AM process steps, including the build process, heat treatment, retrieval from the build plate and removing of support structures, as well as Hot Isostatic Pressing.

The simulation of AM processes can provide information about distortions and residual stresses in the component. These results serve as a basis for the user to meet production tolerances by taking appropriate countermeasures before the part is built.