Heraeus AMLOY turns to Additive Manufacturing for amorphous metal guitar bridge

January 15, 2020

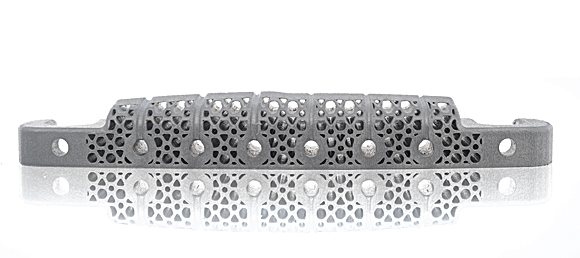

Heraeus AMLOY, a division of Heraeus, Hanau, Germany, reports that it has successfully produced an amorphous metal guitar bridge by metal Additive Manufacturing. The guitar bridge was designed and produced in cooperation with Nik Huber Guitars, a guitar manufacturer based in Rodgau, Germany.

Heraeus AMLOY explained that amorphous metals offer particularly elastic properties, but are at the same time very strong. In addition to their elasticity, amorphous metals are also scratch- and corrosion-resistant. In contrast to conventional materials, it is expected that a guitar bridge made of amorphous metal will not wear out and will not need to be replaced. The material used is also biocompatible and therefore, unlike nickel-plated aluminium bridges, suitable for allergy sufferers.

“Since amorphous metals are significantly more elastic than crystalline materials, they transmit vibrations very well,” stated Jürgen Wachter, Head of Heraeus AMLOY. “Therefore, the material is ideally suited for stringed instruments such as guitars.” In addition to its aesthetic appeal, the company states that the honeycomb structure of the bridge influences its vibration period, dampening vibrations less than closed, solid structures. This changes the sound properties of the instrument..

“One could also imitate the sound of other metals by changing the structures inside the bridge,” added Wachter. “A bridge made of amorphous metal would then sound like a bridge made of brass, for example. The difference is that due to its elasticity it keeps the sound longer, does not wear out and still looks like new even after years.”

Nik Huber, founder and owner of Nik Huber Guitars, has been building guitars with his team for twenty-four years and reportedly enjoys testing new materials such as specialist woods or metals in guitar production. Huber commented, “3D printed amorphous metals are a promising material for guitar building due to their unique properties.”