Gefertec reports on the cost savings offered by its 3DMP Additive Manufacturing technology

April 6, 2018

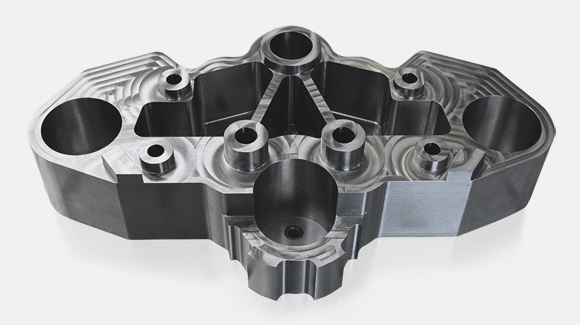

A bearing holder manufactured in nickel-chromium steel 1.4305 on a GTarc system (Courtesy Gefertec GmbH)

Gefertec GmbH, Berlin, Germany, states that its 3DMP® electric arc welding Additive Manufacturing process is the “most economical Additive Manufacturing technology for metal parts.” The company introduced its GTarc machines, which use the 3DMP technology to manufacture metal parts cost-efficiently and at high production speed, late in 2017.

In electric arc Additive Manufacturing, metal parts are constructed by applying welded layers of wire feedstock one on top of the other. Because wire feedstocks are available at a lower cost than AM-suitable metal powders, Gefertec believes that its 3DMP offers a considerably less expensive alternative to many types of metal Additive Manufacturing process.

The company stated that its GTarc machines manufacture near-net-shape metal parts at high speeds and to a quality comparable that achievable using conventional manufacturing methods. Only the finishing of the near-net-shape part is undertaken using standard CNC milling.

In demonstrating the cost-effectiveness of its technology as compared to conventional manufacturing methods, the company referred to the example of an actual part produced on a GTarc machine.

The part – a bearing holder manufactured in nickel-chromium steel 1.4305 – has conventionally been produced by manufacturing an 85 kg block of nickel-chromium steel (452 mm x 245 mm x 100 mm) which is then milled on a CNC machine.

The final milled part weighs only 18 kg – meaning that more than 80% of the material used in this manufacturing process is wasted. The total cost of production amounts to €4,500, including €1,000 in material costs €3,500 in milling costs.

Using 3DMP on a GTarc machine, the near-net-shaped part is said to have weighed only 25 kg and cost €750 to produce. Subsequent milling to net shape was said to have added €1,250 to the overall cost, with 28% material wastage. The comparison identified savings of €2,500, making GTarc’s production process almost 50% less expensive than conventional manufacturing.

Gefertec’s GTarc machines are available in three versions. A 3-axis version, the GTarc 3000-3, is able to produce parts up to 3 m3, while the 5-axis version, the GTarc 800-5 offers an additional pan-tilt-table and is said to be suitable for parts up to 0.8 m3. The company also offers a more compact 5-axis machine, the GTarc 60-5, for parts up to 60 l and 200 kg.

The cost of each GTarc machines is reportedly comparable to a small CNC milling centre, and significantly lower than some alternative AM systems. Each machine is accompanied by CAM software tailored to 3DMP, which draws data from each CAD-modelled part the to enable the Gtarc’s CNC-control unit to correctly position the welding head, enabling high levels of precision.