GE successfully tests AM heat exchanger at temps 200°C higher than standard

June 23, 2021

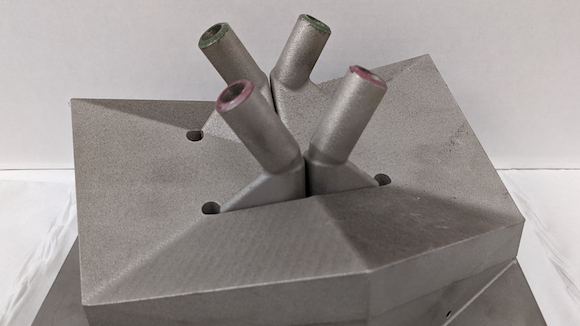

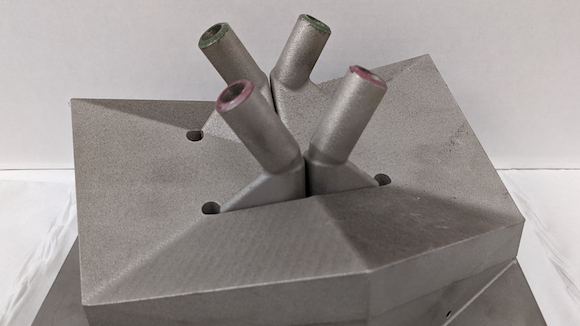

GE Research’s interdisciplinary team, led by Lana Osusky, working with top experts from the University of Maryland and Oak Ridge National Laboratory (ORNL), USA, have successfully built and tested a subscale additively manufactured heat exchanger at temperatures of 900°C and close to half of the 250 bar (3626 psi) pressure set as a goal for the testing. This is said to far exceed many of today’s state-of-the-art devices by more than 200°C.

Beginning in early 2019, GE Research has been leading a $3.1 million project through the Advanced Research Projects Agency’s (ARPA-E) High Intensity Thermal Exchange through Materials and Manufacturing Processes program (HITEMMP) to develop a high temperature, high pressure and super-compact heat exchanger that would enable cleaner, more efficient power generation. The recent breakthrough in the project was reportedly enabled by Additive Manufacturing.

“The design freedom afforded by 3D printing processes and design tools is allowing us to more rapidly develop, build and test new heat exchanger designs that were previously not possible,” commented Lana Osusky, a Lead Engineer at GE Research.

After designing, simulating, building and testing a series of subscale prototypes, the team found success with a unique design of thin-walled unit cells resembling grapes, which was able to handle the higher temperatures and pressure. They observed that a composition of a collection of thin-walled unit cells – as shown in the video – resembled the fruit.

“We may not want to eat these grapes, but we still tasted victory when we completed this key milestone,” she added.

Osusky stated that the GE-led team is on track to build and test its final prototype at both full temperature and pressure by the close of the project in Q1 2022.