GE Additive launches Orthopaedic Validation Consultancy for metal AM medical devices

March 9, 2018

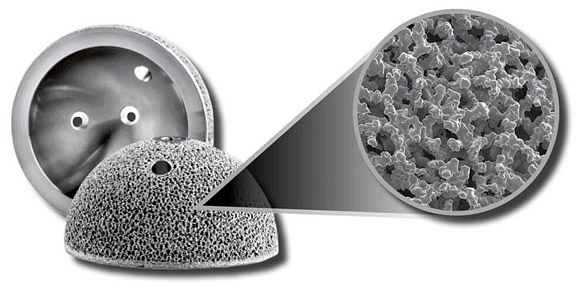

An acetabular / hip cup produced by Arcam EBM (Courtesy GE Additive)

GE Additive has launched a new Orthopaedic Validation Consultancy (OVC) to support its customers through the validation, testing and verification of metal additively manufactured medical devices and implants. The new service was announced during the American Academy of Orthopaedic Surgeons (AAOS) Annual Meeting in New Orleans, Louisiana, USA, March 6-7, 2018, and will be run jointly with GE Additive’s AddWorks Engineering Consultancy.

According to the company, the OVC is designed for medical technology companies using Arcam EBM’s Q10plus metal Additive Manufacturing system to produce devices to strict regulatory and compliancy requirements, including FDA standards, ISO 13485 and other regional and global standards. While available to all of Arcam’s customers in the medical industry, the company stated that it believes the service will add the most value to smaller device firms and start-ups.

Anders Ingvarsson, Product Manager at Arcam EBM, a GE Additive company, stated, “The medical technology sector is up there with the aerospace industry in terms of early adoption of Additive Manufacturing and pushing the boundaries of this emerging technology. There are parallels in the way these two sectors are beginning to incorporate and scale Additive Manufacturing from a prototyping solution into more mainstream production – within a heavily regulated market.”

“We often hear from customers, particularly small to medium-sized medical device companies, that they need guidance and additional resources to help with equipment validation, testing and component verification and also to interpret regulatory and compliance requirements,” he continued. “So, with that in mind, we’ve developed the Orthopaedic Validation Consultancy in conjunction with our colleagues at GE Additive AddWorks to guide our customers through the process.”

The OVC service will be delivered as a collaborative process with GE Additive’s customers over a three to eight-month period, according to Ingvarsson. “Of course, timeframes will vary depending on each customer’s requirement and overall readiness,” he added.

The desired outcome of this collaboration will be twofold; firstly, to decrease component time-to-market and help customers get into production with a validated machine; secondly, to create value in a cost-efficient way. “For some that might mean a faster production start, for others it might be guidance on powder selections and test builds or even advice on how to develop a rigorous risk management strategy,” he explained.

“We have created a five-step approach from assessment through to validation. This way we can provide bespoke modularity and flexibility to map to each customer’s point on their additive journey. With each customer, we create an understanding of the production process, identifying needs and critical parameters and what needs to be tested and proven. Finding joint conclusions are the foundations of the process validation.”

Ingvarsson stated that a number of GE Additive’s customers have already signed up for the consultancy, including large and small enterprises. “Working with the Arcam team during the validation process, we hope that they will be able to acquire deep knowledge and in turn foster a strong Additive Manufacturing mindset within their organisations,” he concluded.