Fraunhofer’s EHLA offers environmentally friendly alternative to chromium (VI) hard chrome plating

October 25, 2017

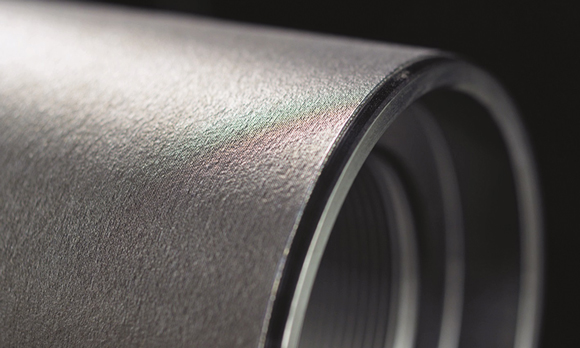

Fraunhofer’s EHLA process has been adopted for applying protective coatings to hydraulic cylinders for maritime use (Courtesy Fraunhofer)

Fraunhofer Institute for Laser Technology (ILT) in Aachen, Germany, reports that its extreme high-speed laser deposition welding process (EHLA) has been adopted as an alternative to now-restricted hexavalent chromium corrosion and wear protection coatings for highly-stressed metal components.

IHC Vremac Cylinders B.V., Apeldoorn, the Netherlands, manufactures hydraulic cylinders which must withstand rough maritime conditions for years at a time. Until now, these cylinders have been coated with hexavalent chromium (chromium(VI)) to protect them from wear and corrosion. Following the introduction of new restrictions on coatings containing this type of chromium, effective in the European Union as of September 2017, the company was forced to source a fast and economical alternative to hard chrome plating.

According to Fraunhofer ILT, IHC Vremac Cylinders is the first company in the world to use the EHLA technique to coat its components. In conventional laser deposition, the laser generates a weld pool on the surface of a component and fuses the metal powder, coaxially added simultaneously, to create the required shape. The powder then fuses with the surface, gradually forming a protective coating.

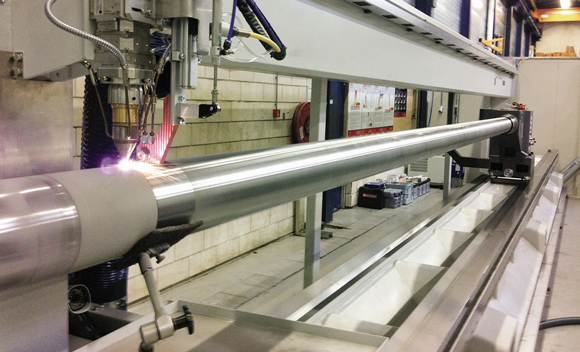

By contrast, in the EHLA method, the laser strikes the powdery filler material above the weld pool, heating the material nearly to its melting point while it is still on its way to the component.

In the EHLA method, a laser heats material nearly to its melting point while it is still on its way to the component (Courtesy Fraunhofer)

Using this technique, coating speeds can reportedly be accelerated from 0.5-2 m per minute to as many as 5 m per minute. The use of EHLA also reduces minimum layer thickness from 500 μm to 25-250 μm, and layers are reported to be smoother, with roughness reduced to a tenth of typical values for Laser Material Deposition.

Having been introduced to the EHLA process by Fraunhofer ILT, IHC Vremac Cylinders contracted Hornet Laser Cladding B.V. – a manufacturer of Laser Material Deposition systems in Lexmond, the Netherlands – to build an EHLA system.

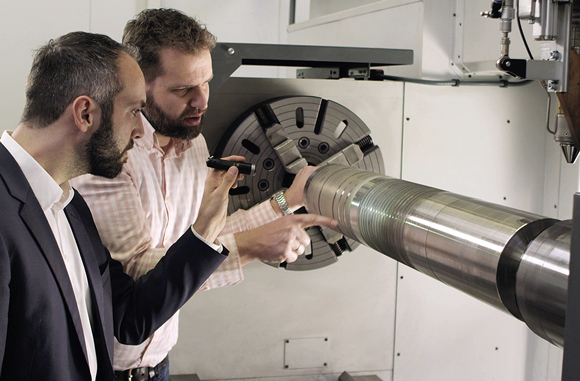

“The advantage of using EHLA to coat rotationally symmetric parts is that the necessary components can be integrated into a lathe,” explained Thomas Schopphoven, head of the Productivity and System Technology team in the Laser Material Deposition group at Fraunhofer ILT, Aachen. IHC Vremac Cylinders stated that it took them less than six months to procure and convert a lathe for the roughly 14-meter-long EHLA system, and thereafter install and commission it.

IHC Vremac Cylinders stated that it took them less than six months to procure and convert a lathe for the roughly 14-meter-long EHLA system (Courtesy Fraunhofer)

“For hydraulic cylinders, we currently apply a protective layer of Inconel 625 some 400 μm thick, which then requires some grinding rework,” explained Andres Veldman, Engineering Manager, IHC Vremac Cylinders. “The final layer thickness is around 200 μm s. EHLA is significantly faster than high-velocity oxygen fuel spraying or HVOF and entails much less post-processing.”

Having completed several projects using EHLA, Veldman reported that this method currently costs roughly the same as thermal spraying. In his view, EHLA will become more economical once the rework processes have been optimised.