Fraunhofer and SIMTech collaborate in Additive Manufacturing and hard coating research

March 10, 2017

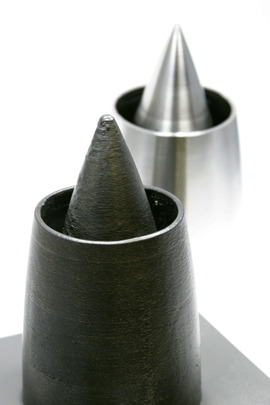

Laser wire build-up of an expansion nozzle (Photo Fraunhofer USA CLA)

Germany’s Fraunhofer IWS Dresden and the Singapore Institute of Manufacturing Technology (SIMTech) have signed a memorandum of understanding for international collaboration in the fields of laser based Additive Manufacturing and diamond-like hard coating technology.

“With the signing of this memorandum of understanding, our collaboration will reach the next level of intensity,” stated Prof Christoph Leyens, Director and Business Unit Manager Additive Manufacturing at Fraunhofer IWS Dresden. “For us, the collaboration with a world-leading institute in Singapore opens up new horizons in the important fields of Additive Manufacturing and coatings technology, both from a scientific and an application-oriented perspective.”

SIMTech is a research institute under Singapore’s Agency for Science, Technology and Research (A*STAR). Through the A*STAR Aerospace Programme, SIMTech has strong links to industry and partnerships with companies in the precision engineering, transportation, oil & gas, energy and electronics sectors. “SIMTech’s collaboration with Fraunhofer IWS will enable us to accelerate the transfer from research to commercialisation, as well as to develop partnerships with industry players, in Singapore and around the world,” stated Dr Jun Wei, Programme Manager at SIMTech.

Fraunhofer IWS has established a major research focus on Additive Manufacturing of metals, ceramics and polymers using various AM processes. The spectrum of applications ranges from, amongst others, aviation, space, medicine, energy, automotive, mechanical engineering and tool making. In collaboration with the TU Dresden, Fraunhofer IWS also recently opened a new innovation centre for Additive Manufacturing.

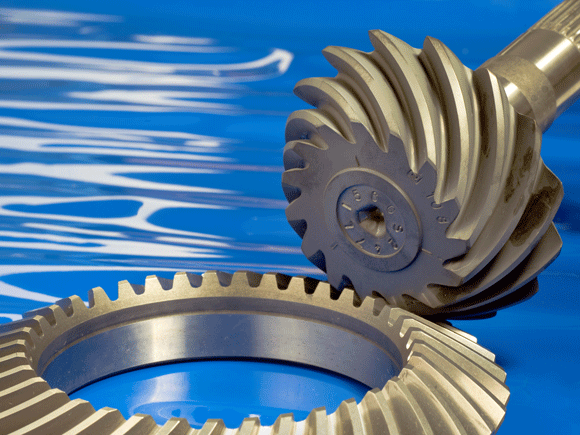

Coating of gear components with super hard Diamor® films by means of laser-arc technology (Photo Frank Höhler)

Diamond-like carbon coatings are widely used in industry, however hydrogen-free DLC-coatings are reported to show even better performance. These coatings are fabricated using a unique laser-arc PVD technology developed at Fraunhofer IWS. “Our coatings are significantly harder and exhibit substantially improved frictional properties relative to state-of-the-art coating solutions,” stated Prof Andreas Leson, Business Unit Manager PVD and Nanotechnology at Fraunhofer IWS. “Since friction and wear occur virtually everywhere, the interest in our innovative coatings is enormous.”