Fraunhofer project futureAM to present its results at Formnext 2019

October 8, 2019

At Formnext 2019, Frankfurt, Germany, November 19-22, the team working on Fraunhofer’s ‘lighthouse project’ futureAM – Next Generation Additive Manufacturing, will present the project’s first tangible results at the joint Fraunhofer booth. Launched in 2017 and comprising an alliance of six Fraunhofer institutes, the project aims to accelerate metal powder-based Additive Manufacturing by at least a factor of ten.

The six futureAM project partners are each said to bring a range of experience in the field of Additive Manufacturing, and entered into the strategic project partnership with two major goals: to establish a comprehensive cooperation platform for the highly integrated cooperation and use of the decentrally distributed resources of the Fraunhofer-Gesellschaft in the field of AM, and to create the technological prerequisites to increase scalability, productivity and quality of AM processes for the production of tailor-made metal components.

The institutes are said to be systematically developing AM in four fields of activity, each coordinated by one institute:

- Industry 4.0 and digital process chains

- Scalable and robust AM processes

- Materials

- System technology and automation

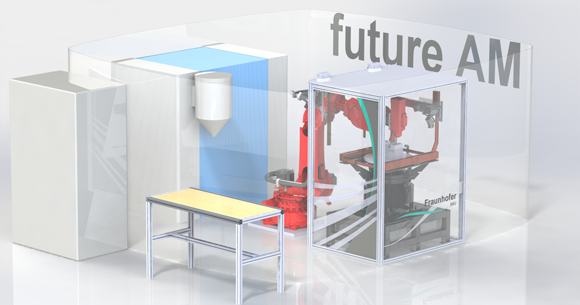

On its launch, the focus project set itself ambitious goals within its four fields of activity. For example, it sought to develop a novel software for automated AM component identification and optimisation, produce a scalable Laser Powder Bed Fusion (L-PBF) plant concept, develop a process and system technology for generating parts with spatially resolved, customised multi-material properties, and create an autonomous manufacturing cell for the post-treatment of AM components.

To facilitate these goals, the partners established a ‘Virtual Lab’, which aims to map the competences and equipment of all institutes involved metal Additive Manufacturing in a closed, digital manner. Each entity – machine or product – within these institutes is described and assigned a digital twin, enabling real systems to be optimised by means of modelling and simulation using its digital equivalent. This is said to enhance error diagnosis, predictive analysis, product and process optimisation and long-term quality assurance.

During Formnext 2019, the team members will showcase the Virtual Lab, which is now ready for operation and currently being evaluated with ‘dummy data’, demonstrating what it can do and how it will work. Fritz Lange, from the Fraunhofer Research Institution for Additive Manufacturing Technologies IAPT in Hamburg,explained, “The institutes will use the Virtual Lab to process and track distributed manufacturing.” Currently, the participating institutes are connecting to the Virtual Lab via their database, meaning that it can soon start its virtual operation.

Among these institutes is the Fraunhofer Institute for Material and Beam Technology IWS in Dresden, which is responsible for developing the materials in the project. This institute will focus on expanding the range of materials that can be processed by means of AM and also on multi-material constructions using Laser Metal Deposition (LMD) to tailor a component from various materials without a downstream joining processes.

“The process accelerates material development enormously,” stated Michael Müller, IWS scientist. “In the joint project, we are investigating which materials can be combined with each other and which problems may arise in the process.” One area currently under investigation is how a multi-material component can be produced from various superalloys. When two materials are joined, the analysis of the transition zone between the materials is particularly important. The researchers have now optimised the material transition from the Inconel 718 to Merl 72 alloys in order to minimise challenges such as crack formation or embrittlement.

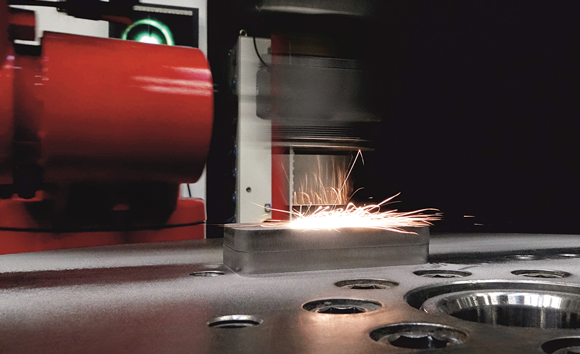

The Fraunhofer Institute for Laser Technology ILT in Aachen is investigating scalable metal AM processes and systems. According to the institute, its engineers have now succeeded in making the step from coating to genuine Additive Manufacturing in extreme high-speed laser material deposition (EHLA). Together with its industrial partners, ILT has developed an EHLA AM in which the construction platform is moved extremely quickly in a parallel kinematic manner by three linear drives with a stationary laser processing head.

Fraunhofer ILT has also developed a new, compact optical system for Laser Powder Bed Fusion (L-PBF). A first prototype of this system is now being used and, with a build volume of 1000 mm x 800 mm x 500 mm, is said to be capable of additively manufacturing large metal components up to ten times faster than conventional L-PBF systems.

The institute has also developed a software model for controlling the energy input when the powder material is remelted. Christian Tenbrock, Research Associate at Fraunhofer ILT and futureAM Project Coordinator, explained, “The process parameters can be set individually for each individual melt track in order to increase both component quality and build speed.”

Fraunhofer Institute for Machine Tools and Forming Technology IWU in Chemnitz is developing various autonomous technology modules for post-processing, with the aim of cutting the high costs involved in manual post-processing steps. IWU’s Dr Ines Dani stated, “Downstream processing steps have not yet been automated, partly because of the different geometries of the parts to be manufactured. This will now change.” In IWU’s autonomous solution, a robot takes over both workpiece handling and post-process machining.

Among the futureAM developments to be presented at Formnext 2019 (Stand D51 Hall 11) will be a bionic lever, exhibited as an example of a large component additively manufactured with ILT’s new L-PBF machine, and a multi-material turbine blade and rocket nozzle with swirl injectors. Also on display will be a model of a system for automated post-processing.