Fraunhofer opens Direct Digital Manufacturing Conference 2023 call for papers

March 18, 2022

The Fraunhofer Competence Field Additive Manufacturing, Dresden, Germany, has issued a call for papers for its Direct Digital Manufacturing Conference (DDMC), scheduled to take place March 15–16, 2023.

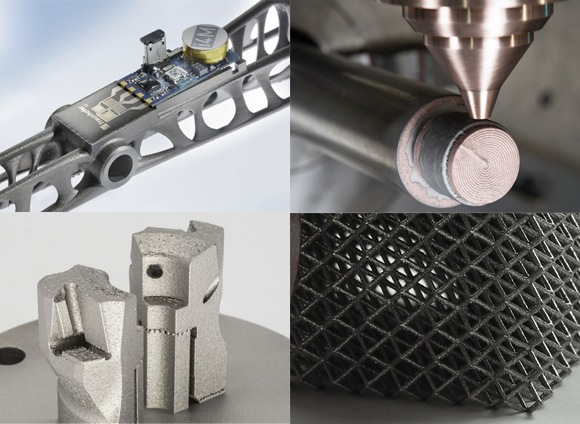

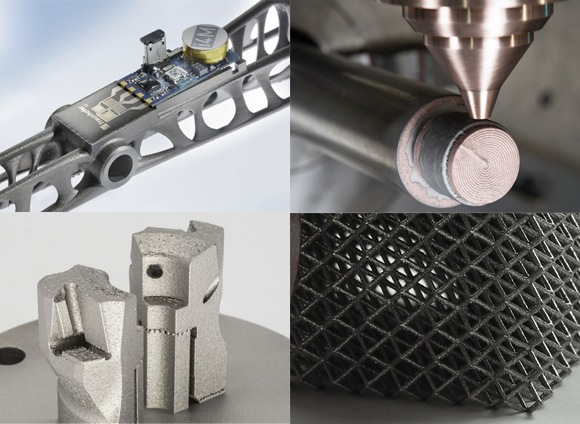

The conference, held bi-annually, is intended to act as a forum for discussions on Additive Manufacturing, including its application in industry and the environmental impact of such new manufacturing technologies. Impact on health, sustainability and society will also be discussed.

Paper topics may include, but are not restricted to:

- Product development, including co-design & mass customisation

- Technologies, including bio-manufacturing, hybrid processes, technological novelties

- Materials, including ceramics, bio-materials, multi-material approaches

- Quality, including process monitoring, part quality management

- Postprocessing, including surface finishing, process chains for industrial production

- Software, including process simulation & automated design

- Latest industrial trends

The deadline for the abstract, a minimum of 250 words, is May 31, 2022. All abstracts will undergo double-blind review. The abstract template and further information on the abstract submission process is available here.

Fraunhofer will also offer a limited number of presentation slots to industry representatives, wherein they can present some of the latest industrial trends to the scientific community. These contributions are only subject to abstract review without the need for a full paper.

DDMC 2023 – Fraunhofer Webinar Series 2022

On April 6, 2022, the first Fraunhofer DDMC webinar will take place. This seminar will inform viewers about breaking Additive Manufacturing news, both from the community at large and Fraunhofer employees. In future webinars, Fraunhofer intends to feature keynote speakers from DDMC 2020, who will review their previous talks and discuss current trends. These webinars are free of charge. Registration is open now.